Bulk Buying Guide: 165mm Soosan SB131/SB140 Chisel Specs

- Bulk Buying Guide: 165mm Soosan SB131/SB140 Chisel Specs

- Product Overview — Hydraulic Breaker Chisel for Soosan SB131/SB140

- Why Choose the 165mm Soosan SB131/SB140 Hydraulic Breaker Chisel?

- Chisel Types, Applications and Selection Criteria

- Chisel Type Comparison (Hydraulic Breaker Chisel)

- Compatibility: Which Breakers Work with 165mm Chisels?

- Material and Manufacturing Quality — Why Cr42 Matters

- Key Specifications to Check When Buying (Hydraulic Breaker Chisel)

- Bulk Buying Advantages: Cost, Inventory, and Downtime Reduction

- How to Calculate True Cost of Ownership for Breaker Chisels

- Inspection, Installation and Best Practices

- Safety Considerations and Operator Guidance (Hydraulic Breaker Chisel)

- Quality Control and Supplier Questions for Bulk Orders

- Delivery, Packaging and Inventory Management

- Brand Advantages — Why Choose Huilian 165mm Soosan Chisels

- Sample Comparison: Unit Cost vs Expected Life (Illustrative)

- How to Place a Bulk Order — Checklist

- FAQ — Hydraulic Breaker Chisel (165mm Soosan SB131/SB140)

- Contact Sales / View Product

- Authoritative References and Further Reading

Bulk Buying Guide: 165mm Soosan SB131/SB140 Chisel Specs

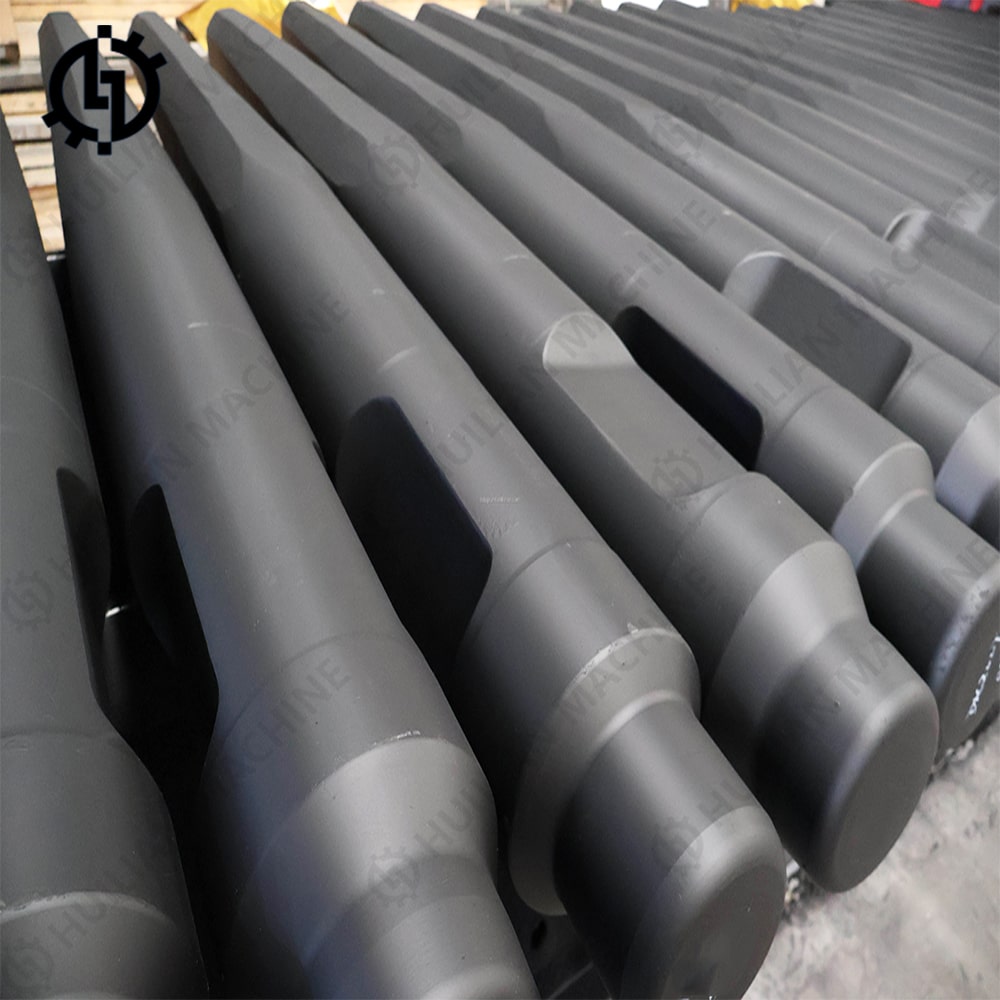

Product Overview — Hydraulic Breaker Chisel for Soosan SB131/SB140

Huilian 165mm Soosan SB131 SB140 SB130 Hydraulic Breaker Chisel features durable D81115 D81118 D81117 D81116 D81119 hydraulic rock hammer parts, including moil point, wedge, blunt cone, and Cr42 rod bits. Ideal for SB131 and SB130 breaker chisels, ensuring high performance and longevity in heavy-duty applications.

Why Choose the 165mm Soosan SB131/SB140 Hydraulic Breaker Chisel?

When buying Hydraulic Breaker Chisel parts in bulk, understanding compatibility, material quality, and the intended application is essential. The 165mm size is a common diameter for medium-to-large carriers and is widely used on Soosan SB131, SB140 and SB130 breakers. These chisels—sold under part numbers D81115, D81118, D81117, D81116, and D81119—are designed for heavy-duty performance in quarrying, demolition, trenching, and road construction.

Chisel Types, Applications and Selection Criteria

Different jobs require different chisel tips. Choosing between moil point, wedge, blunt cone, and Cr42 rod bits affects productivity and tool life. The right tip minimizes downtime and reduces operating cost per ton of rock removed.

Chisel Type Comparison (Hydraulic Breaker Chisel)

| Chisel Type | Typical Use | Main Advantage | Common Part Number(s) |

|---|---|---|---|

| Moil Point | General breaking, medium-hard rock, concrete | Versatile, good penetration and control | D81115 / D81117 |

| Wedge (Flat) | Demolition, splitting, creating controlled break lines | High splitting force, excellent for structural demolition | D81118 |

| Blunt Cone | Tough rock, secondary breaking, large boulders | Durable under high impact, reduces wear in abrasive rock | D81116 |

| Cr42 Rod Bits | Applications requiring high toughness and wear resistance | High fatigue and wear resistance (Cr42 alloy) | D81119 |

Compatibility: Which Breakers Work with 165mm Chisels?

The 165mm chisels are commonly matched with Soosan SB131, SB140 and SB130 breakers. Always confirm with the breaker’s parts manual that the tool diameter, shoulder style, and retaining system match. Installing the wrong shoulder or length can cause premature wear or poor performance. When buying in bulk, request a verification sheet from your supplier listing compatible models and serial ranges.

Material and Manufacturing Quality — Why Cr42 Matters

Cr42 denotes an alloyed steel with higher chromium and carbon content that improves hardness and toughness after proper heat treatment. For Hydraulic Breaker Chisel tools, material quality determines how quickly a chisel will blunt, chip, or crack. Huilian’s Cr42 rod bits are engineered to balance wear resistance and impact toughness—important for heavy-duty uses such as quarrying and concrete demolition.

Key Specifications to Check When Buying (Hydraulic Breaker Chisel)

Before bulk purchasing, collect these minimum specifications from the supplier for each part number:

- Diameter (165mm) and overall length

- Tip type (moil, wedge, blunt cone, rod bit)

- Material grade and heat treatment details (e.g., Cr42, quench and temper)

- Hardness range and tensile strength (if available)

- Shoulder and retaining system compatibility with your breaker model

- Manufacturer warranty and inspection reports

Bulk Buying Advantages: Cost, Inventory, and Downtime Reduction

Purchasing Hydraulic Breaker Chisel tools in bulk lowers unit cost, reduces machine downtime, and streamlines logistics. Consider these gains:

- Price breaks at volume tiers — ask suppliers for 50/100/500+ pricing

- Consistency of parts across fleets reduces stocking variations

- Scheduled replacements reduce emergency freight costs and idle time

How to Calculate True Cost of Ownership for Breaker Chisels

True cost includes purchase price, delivery, installation, expected life (in hours or tons), and replacement downtime. A simple model:

- Unit cost / expected operating hours = cost per hour

- Include downtime cost per hour if replacement requires machine stop time

- Compare cost-per-hour across chisel types; sometimes a higher-cost Cr42 rod bit reduces downtime and net cost

Inspection, Installation and Best Practices

Proper installation and maintenance extend chisel life dramatically. Key steps:

- Inspect the chisel shoulder and tool holder before installation for wear

- Use recommended retaining pins and lubricants from the breaker manual

- Keep a heat-check routine — overheated bushings or striker defects shorten tool life

- Rotate or index chisels when applicable to equalize wear

Safety Considerations and Operator Guidance (Hydraulic Breaker Chisel)

Operators should receive training on proper striking angles, approach speed, and how to avoid hitting rebar or other embedded materials at high risk of gouging the tool. Regular safety checks reduce chisel failure and the risk of injury due to flying fragments.

Quality Control and Supplier Questions for Bulk Orders

When negotiating a bulk purchase, request the following from suppliers:

- Material certificates and heat-treatment logs for Cr42 items

- Dimensional inspection reports and hardness testing (e.g., Rockwell values)

- Sample parts and a first-article inspection (FAI) for large orders

- Warranty terms and replacement policies for defective batches

Delivery, Packaging and Inventory Management

Confirm packaging prevents rust and deformation in transit—oil coating and wooden crates are common. For inventory, maintain a two-week operational buffer for high-use sites, and a 6–12 week buffer for remote or high-risk projects.

Brand Advantages — Why Choose Huilian 165mm Soosan Chisels

Huilian parts for Soosan breakers bring several commercial advantages when buying in bulk:

- Direct cross-reference to Soosan part numbers (D81115–D81119) simplifies procurement

- Cr42 alloy rod bits improve wear life in abrasive environments

- Multiple tip options provide flexibility across job types, reducing the need for stocking many different diameters

- Manufacturers offering certificates, FAI and warranty support reduce risk for fleet managers

Sample Comparison: Unit Cost vs Expected Life (Illustrative)

| Chisel Type | Illustrative Unit Cost (USD) | Expected Life (Hours) | Cost per Hour (USD) |

|---|---|---|---|

| Moil Point | 200 | 500 | 0.40 |

| Wedge | 220 | 550 | 0.40 |

| Blunt Cone | 240 | 650 | 0.37 |

| Cr42 Rod Bit | 280 | 900 | 0.31 |

Note: The table is illustrative. Obtain real quotes and test data from suppliers for accurate planning.

How to Place a Bulk Order — Checklist

Use this checklist when placing a bulk order for Hydraulic Breaker Chisel parts:

- Confirm required part numbers and quantities (D81115, D81118, D81117, D81116, D81119)

- Request certificates, heat-treatment data, and a sample inspection

- Negotiate price tiers and lead times; plan for at least 10–12 weeks supply if needed

- Clarify packaging and rust-prevention methods

- Agree warranty, returns and defective-part handling

FAQ — Hydraulic Breaker Chisel (165mm Soosan SB131/SB140)

Q1: Are D81115–D81119 compatible with Soosan SB131 and SB140?

A: Yes, these part numbers correspond to chisel types designed for 165mm tool bores on Soosan SB131/SB140 and compatible models such as SB130, but always confirm with your breaker’s serial number and parts manual.

Q2: What is the advantage of Cr42 rod bits?

A: Cr42 alloy offers improved fatigue resistance and wear life when properly heat treated, making it a strong choice for abrasive rock and high-impact conditions.

Q3: How many chisels should I keep in stock for a 10-machine fleet?

A: Inventory depends on usage. As a rule of thumb, keep at least 1 spare chisel per machine for daily tasks, plus an additional 20–50% for rotations and unexpected wear. For heavy quarry usage, increase spares to 2–3 per machine.

Q4: Can I re-sharpen or re-tip these chisels?

A: Some chisels can be re-ground to a degree, but material loss and heat can shorten their life. For high-performance Cr42 rods, replacement is usually more cost-effective after significant wear.

Q5: How do I ensure I’m getting genuine quality parts?

A: Request material certificates, hardness tests, and first-article inspection reports. Reputable suppliers provide batch documentation and a clear warranty.

Contact Sales / View Product

If you’re ready to quote or want to view sample parts, contact our sales team for volume pricing, lead time estimates, and technical support. Click to view product pages, request certificates, or schedule a sample inspection today.

Authoritative References and Further Reading

Below are authoritative sources for further technical context on hydraulic breakers, excavators, and material properties:

- Hydraulic breaker — Wikipedia: https://en.wikipedia.org/wiki/Hydraulic_breaker

- Excavator — Wikipedia: https://en.wikipedia.org/wiki/Excavator

- Soosan (Manufacturer & parts information) — https://www.soosan.com/ (manufacturer site)

- Industry guidance on tool steels and heat treatment — general materials resources such as MatWeb: https://www.matweb.com/

For any custom specs, large-volume quotations, or technical compatibility checks, contact our technical sales team with your breaker serial numbers and expected application conditions.

Mini Excavator Hydraulic Breaker Installation and Safety Guide

What is a Hydraulic Breaker? Complete Guide

Wholesale Furukawa hydraulic breaker manufacturer and supplier in China

Top excavator hydraulic breakers Manufacturers and Suppliers

About

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

Huilian OEM Hydraulic Rock Breaker HB40G For FURUKAWA

C71429 SU+165 TR-F SU+165TRF SU165 SU+165 Seal Kit SU+155 Oil Repair Kit For Excavator Attachment SOOSAN Hydraulic Rock Breaker Hammer Spare Part

Huilian OEM Excavator Hydraulic Cylinder Seal Kit 199-7416 For Caterpillar

Introducing the Huilian OEM Excavator Hydraulic Cylinder Seal Kit 199-7416, designed specifically for Caterpillar machinery. Ensure optimal performance and longevity with our premium Cylinder Seal Kit, crafted for durability and precision. Trust Huilian for reliable, top-quality solutions in hydraulic maintenance. Enhance your equipment's efficiency today!

OEM Excavator Spare parts PC2000-8 Track Adjuster Seal Kit For Komatsu

Huilian OEM Excavator Spare Parts PC2000-8 Track Adjuster Seal Kit for Komatsu. Ensures optimal track adjustment performance. High-quality replacement for your PC2000-8 excavator. Order your kit today!

© 2025 HUILIAN MACHINE. All rights reserved