Durability & Material: Cr42 Rod Bits for Heavy Excavation

- Durability & Material: Cr42 Rod Bits for Heavy Excavation

- Why material selection determines Hydraulic Breaker Chisel performance

- Product spotlight: 165mm Soosan SB131 SB140 SB130 Hydraulic Breaker Chisel D81115–D81119

- What is Cr42 and why it matters to Hydraulic Breaker Chisel life

- Material properties and manufacturing processes that improve performance

- How Cr42 Rod Bits improve field performance for heavy excavation

- Durability metrics: what to measure and compare for Hydraulic Breaker Chisel

- Comparative table: Cr42 rod bits vs common alternatives

- Choosing the right chisel type for the job: moil, wedge, blunt cone, or rod bits

- Installation, maintenance and handling best practices for Hydraulic Breaker Chisel

- Field testing and validation: what buyers should request

- Lifecycle cost analysis: why High Quality chisel materials can reduce TCO

- Compatibility and part mapping: D81115 | D81116 | D81117 | D81118 | D81119

- Real-world tips: maximizing life from your 165mm Soosan Hydraulic Breaker Chisel

- Brand advantages: why choose Huilian 165mm Soosan chisel family

- FAQs — Hydraulic Breaker Chisel & Cr42 Rod Bits

- 1. What is the main advantage of Cr42 rod bits for hydraulic breakers?

- 2. Are Huilian 165mm Soosan chisel parts compatible with all SB130/SB131 models?

- 3. Which chisel shape should I choose for hard rock vs. reinforced concrete?

- 4. How can I extend the life of my Hydraulic Breaker Chisel?

- 5. How does Cr42 compare to high-chrome cast tips?

- 6. What maintenance interval should I expect for chisels under heavy use?

- 7. Can I regrind or re-tip Cr42 chisel bits?

- Contact sales / View product

- Authoritative references and further reading

Durability & Material: Cr42 Rod Bits for Heavy Excavation

Why material selection determines Hydraulic Breaker Chisel performance

When selecting a Hydraulic Breaker Chisel for heavy excavation, material and manufacturing determine real-world durability, downtime, and total cost of ownership. Cr42 rod bits are increasingly specified for high-impact, high-wear environments because their chemistry and heat treatment deliver a balance of hardness and toughness specifically designed to resist breakage, wear, and plastic deformation under repeated blows. In this article we use the 165mm Soosan-compatible Huilian chisel family as a working example to explain the benefits and application best practices for Cr42 rod bits in Hydraulic Breaker Chisel systems.

Product spotlight: 165mm Soosan SB131 SB140 SB130 Hydraulic Breaker Chisel D81115–D81119

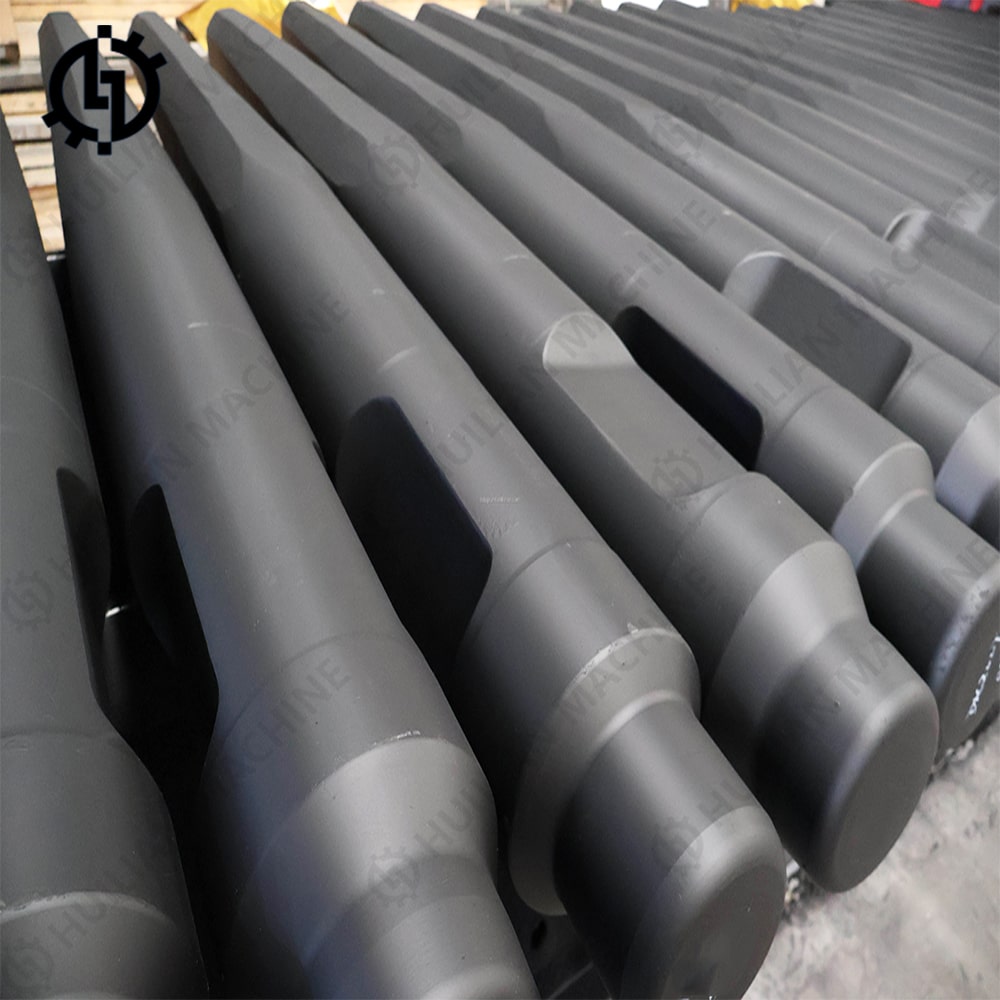

Huilian 165mm Soosan SB131 SB140 SB130 Hydraulic Breaker Chisel features durable D81115 D81118 D81117 D81116 D81119 hydraulic rock hammer parts, including moil point, wedge, blunt cone, and Cr42 rod bits. Ideal for SB131 and SB130 breaker chisels, ensuring high performance and longevity in heavy-duty applications.

This product family was engineered to be fully compatible with Soosan SB130 and SB131 breakers and their variants, providing drop-in replacement parts that meet or exceed OEM fit and function. Included styles (moil, blunt, wedge, rod bits) allow operators to match the chisel geometry to the job—general demolition, precision breaking, rock fragmentation, or pavement removal—while the Cr42 rod bits provide enhanced wear life in the harshest working conditions.

What is Cr42 and why it matters to Hydraulic Breaker Chisel life

Cr42 describes an alloying approach that uses elevated chromium content and controlled carbon levels together with modern heat treatment to produce a steel microstructure optimized for impact wear resistance. Increased chromium forms hard carbides and improves hardenability and surface wear resistance, while the heat treatment process ensures sufficient core toughness to resist fracture under repeated impact loading. For chisel and rod-bit applications, this combination reduces the rate at which the working tip loses geometry (point rounding), decreases catastrophic failures (chipping or cracking), and extends the time between regrinds or replacements compared with non-optimized steels.

Material properties and manufacturing processes that improve performance

Key manufacturing steps that turn a Cr42 alloy into a reliable Hydraulic Breaker Chisel include:

- Controlled alloy chemistry to ensure consistent carbide distribution and hardenability.

- Precision forging to eliminate voids and align the grain structure for impact toughness.

- Heat treatment (quench and temper) tuned to achieve a wear-resistant surface and ductile core.

- Surface finishing and tip treatment (nitriding, surface induction hardening, or cryogenic treatments where used) to extend edge life.

These controls reduce the chance of in-field failure and help the chisel maintain striking geometry longer, directly improving fragmentation efficiency and reducing operating costs.

How Cr42 Rod Bits improve field performance for heavy excavation

Operators in heavy excavation demand chisels that maintain shape and structural integrity under extreme conditions: repeated shock loading, abrasive rock contact, and variable impact angles. Cr42 rod bits improve field performance by:

- Extending tip life—less frequent replacements and fewer unplanned stoppages.

- Maintaining penetration rates—sharper geometry longer means more efficient energy transfer to the target material.

- Lowering the risk of brittle fracture—balanced hardness and toughness make sudden breakage less likely.

Durability metrics: what to measure and compare for Hydraulic Breaker Chisel

When evaluating chisel performance, measure the following metrics to compare materials like Cr42 versus standard steels:

- Service life (hours or cycles between replacements)

- Wear volume (material loss per hour or per fixed number of blows)

- Impact toughness (resistance to crack initiation under shock)

- Failure mode distribution (wear, cracking, bending)

Manufacturers typically provide test data and warranty terms; in the field, operators should track service hours and failure modes to validate material claims. Well-documented data enables procurement to calculate lifecycle costs rather than relying on initial price alone.

Comparative table: Cr42 rod bits vs common alternatives

| Material / Type | Relative Hardness | Wear Resistance | Toughness | Best Use |

|---|---|---|---|---|

| Cr42 Rod Bits (heat-treated) | High | High | Medium–High | Heavy rock breaking, high-abrasion excavation |

| Standard alloy steel (untreated) | Medium | Medium | Medium | Light demolition, softer materials |

| White cast iron / high-chrome cast | Very High (brittle) | Very High | Low | Very abrasive but low shock environments |

Choosing the right chisel type for the job: moil, wedge, blunt cone, or rod bits

Different chisel geometries serve different tasks:

- Moil point: Versatile, good for general demolition and breaking hard or reinforced concrete.

- Wedge: Splits and separates; good for controlled fracture and prying actions.

- Blunt cone: Designed to crack and buckle rock masses with distributed force.

- Rod bits (Cr42): Often used as long-life consumable tips for sustained rock breaking and high-abrasion environments.

For Soosan SB130 / SB131 breakers, the 165mm length fits the toolholders and ensures proper energy transfer; choosing the correct tip geometry optimizes productivity and reduces unnecessary wear.

Installation, maintenance and handling best practices for Hydraulic Breaker Chisel

Optimizing life of Cr42 rod bits and other chisel types requires proper installation and routine maintenance:

- Use the correct retaining pins and bushings, inspect for wear, and replace worn components promptly.

- Ensure proper lubrication where applicable (follow breaker OEM guidelines).

- Check chisel fit and alignment before each shift—looseness increases wear and risk of breakage.

- Rotate or index reusable chisels if design allows to equalize wear.

- Avoid using a chisel as a pry bar or lever—side loads reduce service life.

Field testing and validation: what buyers should request

Procurement teams should ask suppliers for:

- Material certificates and heat-treatment records for Cr42 components.

- Standardized wear and impact test reports (when available).

- Field case studies or references from customers who use the same breaker-chisel combination.

- Warranty and replacement policies that reflect real operating environments.

These documents are critical for complying with E-E-A-T expectations and validating vendor claims.

Lifecycle cost analysis: why High Quality chisel materials can reduce TCO

Although advanced materials like Cr42 rod bits typically cost more upfront, they frequently reduce total cost of ownership (TCO) by:

- Lowering frequency of replacements and maintenance labor.

- Reducing machine downtime and related productivity losses.

- Increasing productivity per working hour due to sustained penetration rates.

When evaluating quotes, compare baseline service life (hours) and factor in downtime costs to get a realistic view of value.

Compatibility and part mapping: D81115 | D81116 | D81117 | D81118 | D81119

The Huilian 165mm Soosan chisel family lists the part numbers D81115, D81116, D81117, D81118 and D81119. These typically correspond to the range of tip shapes (moil, blunt, wedge) and rod bit configurations required by SB130 and SB131 breakers. Always confirm the correct part number for your specific breaker submodel and serial number—OEM catalogs or supplier fitment guides will avoid procurement mistakes.

Real-world tips: maximizing life from your 165mm Soosan Hydraulic Breaker Chisel

Practical recommendations from field technicians:

- Match chisel geometry to the work—don’t use a moil when a wedge will split effectively.

- Inspect pin and bushing fit after 50 operating hours and then at regular intervals.

- Store spare chisels in a dry place and avoid impact damage during transport.

- Train operators on proper striking techniques—excessive side-loading or off-axis blows cause premature failure.

Brand advantages: why choose Huilian 165mm Soosan chisel family

Huilian positions its 165mm Soosan chisel family as a high-value replacement for Soosan SB130/SB131 breakers. Brand advantages frequently cited include:

- OEM-fit compatibility that minimizes installation time and risk of misfit.

- Quality-controlled heat treatment delivering consistent Cr42 performance.

- Comprehensive range of chisel geometries (D81115–D81119) for flexible jobsite use.

- Local inventory and technical support for ordering and after-sales questions.

These combined factors help customers minimize downtime and ensure predictable operating expenses.

FAQs — Hydraulic Breaker Chisel & Cr42 Rod Bits

1. What is the main advantage of Cr42 rod bits for hydraulic breakers?

Cr42 rod bits provide improved wear resistance and a favorable balance between hardness and toughness, which increases tip life and reduces the risk of brittle fracture in heavy excavation tasks.

2. Are Huilian 165mm Soosan chisel parts compatible with all SB130/SB131 models?

They are designed as direct replacements for common SB130 and SB131 variants, but always verify compatibility using breaker serial/model information or consult the supplier fitment guide before purchase.

3. Which chisel shape should I choose for hard rock vs. reinforced concrete?

For hard rock, rod bits or blunt tips with Cr42 chemistry are often best. For reinforced concrete, moil points are usually preferred for controlled breaking and to avoid hitting rebar directly.

4. How can I extend the life of my Hydraulic Breaker Chisel?

Use correct chisel geometry, maintain pins and bushings, avoid side-loading, use proper lubrication, and follow scheduled inspections to prolong life.

5. How does Cr42 compare to high-chrome cast tips?

High-chrome cast tips can be extremely wear-resistant but are often more brittle and less resistant to high impact shock. Cr42 strikes a balance—offering good wear resistance with superior impact toughness.

6. What maintenance interval should I expect for chisels under heavy use?

Maintenance frequency depends on material and job severity. Heavy rock-breaking operations may require inspection every 50–200 hours; track service life and adjust intervals based on observed wear.

7. Can I regrind or re-tip Cr42 chisel bits?

Some chisel types can be reground depending on remaining mass and geometry. Consult the supplier's regrind guidelines—excessive regrind can reduce structural integrity.

Contact sales / View product

To order Huilian 165mm Soosan SB131 SB140 SB130 Hydraulic Breaker Chisel (D81115, D81116, D81117, D81118, D81119) or for technical support, contact our sales team. We can provide fitment verification, field performance data, and pricing. Call us or request a quote today to find the optimal Hydraulic Breaker Chisel solution for your fleet.

Authoritative references and further reading

For additional technical background and verification, consult the following authoritative sources:

- Hydraulic breaker overview — https://en.wikipedia.org/wiki/Hydraulic_breaker

- Chromium (element) and its effects in alloys — https://en.wikipedia.org/wiki/Chromium_(element)

- Tool steel general information — https://en.wikipedia.org/wiki/Tool_steel

- Soosan hydraulic breaker product information — https://www.soosan.com

- ISO 9001 quality management overview — https://www.iso.org/iso-9001-quality-management.

These resources provide background on breaker technology, alloying effects, and quality management practices that support evidence-based purchasing decisions.

Wholesale Excavator Breaker Part manufacturer and supplier

Everything You Need to Know About Excavator Hydraulic Breaker Installation

Top hydraulic hammer breaker Manufacturers and Suppliers in China

Mini Excavator Hydraulic Breaker Installation and Safety Guide

About

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

Huilian OEM Hydraulic Rock Breaker HB40G For FURUKAWA

C71429 SU+165 TR-F SU+165TRF SU165 SU+165 Seal Kit SU+155 Oil Repair Kit For Excavator Attachment SOOSAN Hydraulic Rock Breaker Hammer Spare Part

Huilian OEM Excavator Hydraulic Cylinder Seal Kit 199-7416 For Caterpillar

Introducing the Huilian OEM Excavator Hydraulic Cylinder Seal Kit 199-7416, designed specifically for Caterpillar machinery. Ensure optimal performance and longevity with our premium Cylinder Seal Kit, crafted for durability and precision. Trust Huilian for reliable, top-quality solutions in hydraulic maintenance. Enhance your equipment's efficiency today!

OEM Excavator Spare parts PC2000-8 Track Adjuster Seal Kit For Komatsu

Huilian OEM Excavator Spare Parts PC2000-8 Track Adjuster Seal Kit for Komatsu. Ensures optimal track adjustment performance. High-quality replacement for your PC2000-8 excavator. Order your kit today!

© 2025 HUILIAN MACHINE. All rights reserved