Inventory & Maintenance Strategies for Cr42 Rock Breaker Parts

- Inventory & Maintenance Strategies for Cr42 Rock Breaker Parts

- Why focused inventory for Hydraulic Rock Breaker chisel parts matters

- Assessing criticality: which SB151 chisel parts to stock first

- Estimating wear life and planning reorder points for Cr42 chisels

- Vendor & procurement strategies for quicker replenishment of C71157–C71161 parts

- Preventive maintenance schedule for SB151 breaker chisels

- Condition-based maintenance and monitoring to reduce parts consumption

- Repair vs replace: economic decision-making for Cr42 chisels

- Spare parts kit configuration for the field: SB151 chisel set checklist

- Maintenance tooling and consumables to stock

- Quality & compatibility: ensuring you buy the right 175mm Cr42 chisel for Soosan SB151

- Brand advantages: Why choose Huilian 175mm SB151 chisel set for your inventory

- Cost-control and KPI tracking for rock breaker consumables

- Implementation checklist: get your inventory & maintenance program running

- FAQ — Inventory & Maintenance for Cr42 Rock Breaker Parts

- Contact & product call-to-action

- Authoritative references

Inventory & Maintenance Strategies for Cr42 Rock Breaker Parts

Why focused inventory for Hydraulic Rock Breaker chisel parts matters

For contractors and rental fleets using hydraulic breakers, unplanned downtime from a worn or missing chisel quickly becomes an expensive productivity problem. The 175mm Cr42 chisel Soosan SB151 Hydraulic Hammer C71157 C71158 C71160 C71159 C71161 Moil Point Wedge Blunt Cone Rod Bits Tool Rock Breaker Parts is a comprehensive set specifically engineered for Soosan SB151 hydraulic breakers. The Huilian 175mm SB151 chisel set includes Moil Point, Wedge, Blunt, Cone, and Rod Bits, perfectly designed for Soosan SB151 hydraulic breakers. Durable and precise, these SB151 breaker chisels and tools ensure efficient rock breaking and long-lasting performance. A deliberate inventory strategy focusing on these specific part numbers (C71157–C71161) and the Hydraulic Rock Breaker chisel family avoids excessive stock, minimizes capital tied up in parts, and ensures field crews spend more time breaking rock and less time waiting for replacements.

Assessing criticality: which SB151 chisel parts to stock first

Not all parts are equally critical. Use an ABC analysis tailored to the Soosan SB151 chisel set to prioritize stocking levels:

- Category A — High criticality and high consumption: Moil Point (primary working tool), Rod Bits, and retaining pins. Stock these in larger quantities.

- Category B — Moderate criticality: Wedge and Blunt chisels used for specific tasks. Keep a moderate buffer stock.

- Category C — Low criticality or longer life: Cone chisels or specialty bits. Keep minimal spare inventory or order on demand.

Estimating wear life and planning reorder points for Cr42 chisels

Wear life depends on material, application, operator technique, and ground conditions. Typical field experience for 175mm Cr42 chisels on a Soosan SB151 falls into broad ranges (estimates based on typical conditions):

| Chisel Type | Typical Life (hours) | Primary Failure Mode | Suggested On-Hand Quantity (per breaker) |

|---|---|---|---|

| Moil Point | 200–800 hrs | Tip wear & deformation | 2–4 |

| Wedge | 300–1000 hrs | Edge wear, chipping | 1–2 |

| Blunt | 250–900 hrs | Surface spalling | 1–2 |

| Cone | 300–1200 hrs | Wear at shoulder | 1 |

| Rod Bits / Tool Rod | 400–1500 hrs | Bending / fatigue | 1–2 |

Use these ranges as starting points. For high-impact sites (hard rock, contaminated ground) assume the low end of estimates; for softer ground, expect longer life. Calculate reorder points using lead time (supplier delivery days), daily usage rate, and safety stock: Reorder Point = (Daily Usage × Lead Time) + Safety Stock.

Vendor & procurement strategies for quicker replenishment of C71157–C71161 parts

Faster procurement reduces on-site stock requirements. Best practices:

- Establish a vendor-managed inventory (VMI) arrangement for the SB151 chisel set so the supplier keeps a small warehouse close to your sites.

- Negotiate consignment inventory or blanket purchase orders for C71157–C71161 to lower lead times and lock in pricing.

- Keep a preferred supplier list including OEM and high-quality aftermarket vendors (e.g., Huilian) with verified part compatibility for Soosan SB151 breakers.

Preventive maintenance schedule for SB151 breaker chisels

Regular preventive maintenance prolongs chisel life and protects the hydraulic breaker. A recommended routine for Soosan SB151 breakers and the 175mm Cr42 chisel set:

- Daily (pre-shift): Visual inspection for cracks, chips, and loose retainers; check chisel seating and hammer oil level.

- Weekly: Clean dust seals, inspect nitrogen chamber pressure (if applicable), and check hammer accumulator settings.

- Monthly or every 100–200 hours: Measure chisel tip dimensions and compare against wear limits; rotate or replace chisels showing excessive wear.

- Every 500 hours or per manufacturer guidance: Full teardown inspection—check bushings, tool retaining system, and piston condition.

Condition-based maintenance and monitoring to reduce parts consumption

Move beyond time-based maintenance by using condition indicators:

- Track vibration signatures and hammer impact consistency—sudden changes may indicate chisel deformation or looseness.

- Log chisel hours by serial number to estimate remaining life more accurately.

- Use a simple scoring system at inspection (0–5) for tip condition, body wear, and seat fit—to trigger replacements only when needed.

Repair vs replace: economic decision-making for Cr42 chisels

Replacing worn chisels is not always the only option. Consider these criteria when deciding:

- Extent of wear: Chisels worn beyond manufacturer-specified dimensions should be replaced for safety and efficiency.

- Repairability: Some chisels can be re-machined or re-hardened—feasible for minor tip wear but often uneconomic for heavily fatigued rods.

- Cost & downtime tradeoff: If repair lead time exceeds replacement procurement lead time, replacement is usually preferred.

Spare parts kit configuration for the field: SB151 chisel set checklist

Create a compact field kit for each Soosan SB151 unit to handle common failures without returning to base. Recommended kit contents:

- 2 × Moil Point (C71157 compatible)

- 1 × Wedge (C71158 compatible)

- 1 × Blunt (C71160 compatible)

- 1 × Cone (C71159 compatible)

- 1 × Rod Bit / tool rod (C71161 compatible)

- 2 × Retaining pins and springs, spare bushings

- Grease, hammer oil, simple measurement gauges, safety tools

Maintenance tooling and consumables to stock

Alongside chisels, maintain stocks of consumables and small parts that often cause delays:

- Retaining pins, O-rings, dust seals, bushings

- Approved hydraulic hammer oil and grease

- Spare accumulator nitrogen service components (as needed)

- Torque tools, chisel removal devices, and simple inspection gauges

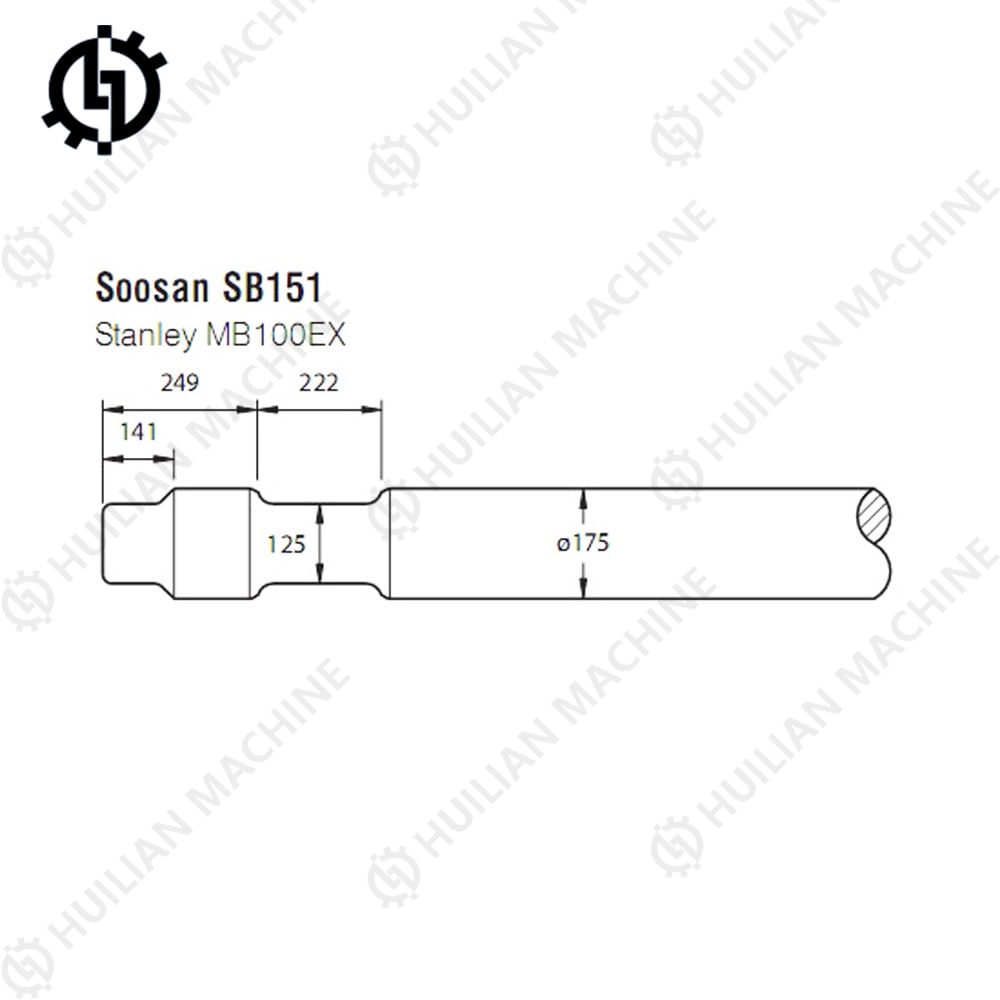

Quality & compatibility: ensuring you buy the right 175mm Cr42 chisel for Soosan SB151

Ensure parts like the 175mm Cr42 chisel are compatible with Soosan SB151 breakers by:

- Verifying part numbers C71157, C71158, C71160, C71159, C71161 match breaker specifications.

- Requesting material certificates (Cr42 composition) and heat-treatment documentation from suppliers.

- Choosing suppliers with proven warranty and testing procedures. OEM-equivalent hardness and geometry minimize seating issues and premature wear.

Brand advantages: Why choose Huilian 175mm SB151 chisel set for your inventory

When integrating parts into your inventory strategy, product reliability and supplier support are critical. The Huilian 175mm SB151 chisel set offers several advantages:

- Complete set: Moil Point, Wedge, Blunt, Cone, and Rod Bits packaged for immediate use in Soosan SB151 breakers.

- Material and heat treatment optimized for Cr42 specifications, improving wear resistance.

- Consistent dimensional tolerances reduce seating and fit issues, simplifying maintenance tasks in the field.

- Supplier support: readily available documentation and spares for quick procurement cycles.

Cost-control and KPI tracking for rock breaker consumables

Track a few straightforward KPIs to manage inventory and maintenance economics:

- Parts availability rate (target >95% for Category A items)

- Mean time between failures (MTBF) for chisels

- Cost per operating hour attributable to consumables

- Stock turnover rate for SB151 chisel parts

Implementation checklist: get your inventory & maintenance program running

Use this step-by-step checklist to implement the strategies described:

- Identify current usage and failure patterns for each chisel type (C71157–C71161).

- Perform ABC analysis and define target on-hand quantities.

- Set reorder points using lead time and usage rates; implement VMI or consignment if possible.

- Deploy preventive and condition-based maintenance routines; log chisel serials and hours.

- Create field kits and stock critical consumables (retainers, seals, oil).

- Track KPIs and refine stocking levels quarterly based on data.

FAQ — Inventory & Maintenance for Cr42 Rock Breaker Parts

Q1: How often should I replace a 175mm Cr42 Moil Point on a Soosan SB151?

A: Typical life ranges from 200–800 hours depending on ground conditions. Inspect tip geometry weekly and replace when tip dimensions fall below manufacturer tolerance or when productivity drops.

Q2: Are Huilian 175mm SB151 chisels compatible with all Soosan SB151 breakers?

A: The Huilian set is designed specifically for Soosan SB151 models. Always verify part numbers (C71157–C71161) and confirm fit before bulk procurement.

Q3: Can chisels be rebuilt instead of replaced?

A: Minor tip repairs and re-hardening are possible but often uneconomic beyond certain wear thresholds. Perform a cost-per-hour analysis to decide.

Q4: What safety items should be in the field kit?

A: Include retaining pins, seals, basic tools, approved hammer oil, chisel extractor, gloves, goggles, and a basic inspection gauge.

Q5: How many spare Moil Points should I stock per breaker?

A: A practical recommendation is 2–4 moil points per breaker to cover typical wear and short lead times—adjust based on your site's hardness and supplier lead times.

Contact & product call-to-action

To reduce downtime and optimize your parts inventory, inquire about the 175mm Cr42 Chisel Soosan SB151 Hydraulic Hammer C71157 C71158 C71160 C71159 C71161 Moil Point Wedge Blunt Cone Rod Bits Tool Rock Breaker Parts from Huilian. Contact our sales team for pricing, lead times, and to set up a vendor-managed inventory plan. Click to view the product or request a quote and technical datasheet — proactive stocking and preventive maintenance will maximize your fleet uptime.

Authoritative references

For technical background and safety guidance consult these authoritative sources:

- Hydraulic breaker general reference — Wikipedia: https://en.wikipedia.org/wiki/Hydraulic_breaker

- Soosan official site (hydraulic breaker manufacturer): https://www.soosan.com/

- Epiroc technical resources for rock-drilling tools: https://www.epiroc.com/

- UK Health & Safety Executive (construction plant safety): https://www.hse.gov.uk/

- ISO (quality and conformity standards information): https://www.iso.org/

Top hydraulic hammer breaker Manufacturers and Suppliers in China

Wholesale Komac hydraulic breaker manufacturer and supplier in China

Wholesale Fine hydraulic breaker manufacturer and supplier in China

Wholesale hydraulic cylinder seal kits manufacturer and supplier

About

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

175mm Cr42 Chisel Soosan SB151 Hydraulic Hammer C71157 C71158 C71160 C71159 C71161 Moil Point Wedge Blunt Cone Rod Bits Tool Rock Breaker Parts

165mm Soosan SB131 SB140 Hydraulic Breaker Chisel D81115 D81118 D81117 D81116 D81119 SB130 Rock Hammer Parts Cr42 Rod Bits Tool

Huilian 165mm Soosan SB131 SB140 SB130 Hydraulic Breaker Chisel features durable D81115 D81118 D81117 D81116 D81119 hydraulic rock hammer parts, including moil point, wedge, blunt cone, and Cr42 rod bits. Ideal for SB131 and SB130 breaker chisels, ensuring high performance and longevity in heavy-duty applications.

Cr42 155mm Chisel Soosan SB121 Hydraulic Breaker Parts C61227 C61228 C61230 C61229 C61231 Rock Hammer Moil Point Wedge Blunt Cone Rod Bits Tool

Huilian’s Cr42 155mm SB121 chisel delivers superior durability for Soosan SB121 hydraulic breakers. Compatible with parts C61227, C61228, C61229, C61230, and C61231, this rock hammer tool enhances performance with moil point, wedge, blunt cone, and rod bit options.

Soosan SB100 Hydraulic Breaker Chisel Cr42 150mm E91113 E91114 E91115 E91116 E91117 Rock Hammer Part Moil Point Wedge Blunt Cone Rod Bits Tool

The Huilian Soosan SB100 Hydraulic Breaker Chisel Cr42 150mm offers durable, high-performance SB100 chisel options including moil point, wedge, blunt, and cone bits. Ideal for heavy-duty rock hammer tasks, these SB100 breaker chisels ensure precise, reliable impact in all conditions.

© 2025 HUILIAN MACHINE. All rights reserved