How to Properly Size Your Hydraulic Hammer

- How to Properly Size Your Hydraulic Hammer

- Understanding the Importance of Correct Hydraulic Hammer Sizing

- Key Factors in Hydraulic Hammer Sizing

- Matching Hammer to Carrier: Sizing Guidelines

- Considering Operational Environment

- Calculating Impact Rate and Energy Output

- The Advantages of Correct Sizing

- The Risks of Oversizing or Undersizing

- Proper sizing is not only a technical issue but a matter of long-term ROI and safety.

- Huilian’s Comprehensive Solutions for Hydraulic Hammers

- How to Request Sizing Support from Huilian

- Maintenance Tips for Your Hydraulic Hammer

- FAQs

How to Properly Size Your Hydraulic Hammer

Hydraulic hammers—also known as hydraulic breakers—are critical attachments for excavators, significantly boosting efficiency in demolition, quarrying, construction, and mining industries. However, maximizing the potential of your hydraulic hammer requires selecting the correct size for your equipment and application. Sizing your hydraulic hammer properly not only increases productivity but also extends the life of both your breaker and your carrier. As a leading supplier and OEM of excavator parts since 2005, Huilian Machine is committed to providing our customers worldwide with the expertise necessary for optimal performance and longevity of their machines. In this guide, we’ll discuss how to properly size your hydraulic hammer to fit your excavator and specific operational needs.

Understanding the Importance of Correct Hydraulic Hammer Sizing

Correctly sizing your hydraulic hammer is crucial for safety, machinery longevity, and operational efficiency. An undersized hammer will underperform and wear out quickly, while an oversized one can damage your excavator or increase operating costs. Understanding how to properly size your hydraulic hammer ensures the optimal match between power, weight, and carrier compatibility, contributing to energy efficiency and operational cost savings.

Key Factors in Hydraulic Hammer Sizing

Several key factors must be considered in how to properly size your hydraulic hammer, including carrier weight, hydraulic flow and pressure, the type of work, and material hardness. Failing to consider these factors can lead to costly downtime, maintenance, or unsafe working conditions.

Carrier Weight and Compatibility

Carrier compatibility is the foundation of hydraulic hammer performance. The weight and capability of your excavator (the carrier) directly impact the size and power of the hammer you can safely and efficiently use. Typically, each hydraulic hammer model has a recommended carrier weight range. Using a hammer that’s too large for your excavator can cause stability issues and undue mechanical stress; while a hammer that’s too small won't take full advantage of your carrier’s power.

Hydraulic Flow and Pressure Requirements

Each hydraulic hammer requires a specific oil flow and pressure range to work correctly. If your carrier provides more or less than the required flow, the hammer will not operate efficiently, risking damage to both the attachment and the excavator. Always check your carrier's hydraulic specifications and match them with the hammer’s requirements for optimal performance.

Application and Material Type

How to properly size your hydraulic hammer also depends on the materials you need to break. For instance, secondary demolition (breaking apart smaller, pre-broken pieces) often requires a smaller hammer, while primary breaking in quarries or mining sites requires larger, more powerful equipment. Assess the hardness and density of the material—softer materials (like limestone or brick) need less impact energy than harder materials (like reinforced concrete or granite).

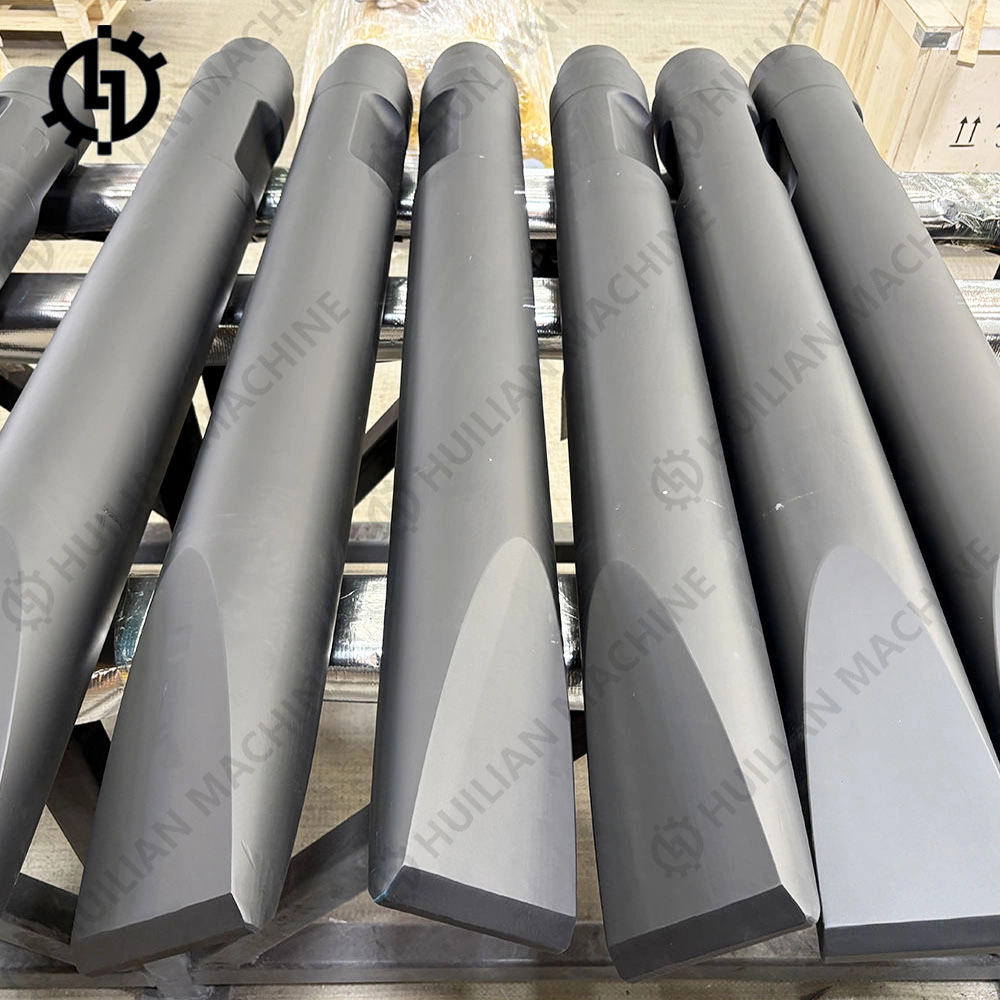

Tool Diameter and Impact Energy

Hydraulic hammer sizes are often classified by tool diameter and impact energy. The chisels, pistons, and working tools provided by Huilian Machine come in a range of sizes to suit various tasks. A larger tool diameter and higher impact energy are recommended for heavy-duty jobs, while smaller tool sizes are suitable for precision work.

Matching Hammer to Carrier: Sizing Guidelines

Matching the right hydraulic hammer to your excavator requires a balanced approach. Below are general guidelines based on industry standards and Huilian Machinery’s expertise:

- 1-7 Ton Carriers: Hammers with tool diameters of 45-75 mm, ideal for light demolition, landscaping, or small foundation work.

- 8-15 Ton Carriers: Medium hammers, tool diameters of 75-100 mm, for trenching, road construction, or utility work.

- 16-30 Ton Carriers: Heavy-duty hammers, tool diameters of 100-135 mm, for quarry work, heavy demolition, or breaking large rocks and concrete.

- 31-70 Ton Carriers: Extra heavy hammers, tool diameter above 135 mm, suitable for mining, primary breaking in large quarries, and major infrastructure projects.

*Always refer to the manufacturer’s guidelines to ensure compatibility. If in doubt, consult Huilian’s team of R&D experts for a personalized recommendation.*

Considering Operational Environment

The operational environment significantly influences how to properly size your hydraulic hammer. In confined urban construction sites, a smaller, quieter hammer might be required to minimize noise and vibrations, whereas open quarries allow for larger hammers that maximize productivity.

Calculating Impact Rate and Energy Output

Beyond size, consider the impact rate (blows per minute) and impact energy (joules or foot-pounds) required for your application. Some operations benefit from a higher impact rate, while others require more force per blow. Huilian's wide range of hydraulic breakers offers customizable settings to precisely match your operational requirements.

The Advantages of Correct Sizing

Choosing the right hydraulic hammer size means:

- Enhanced productivity and fuel efficiency

- Extended machine and attachment lifespan

- Improved operator safety

- Reduced maintenance and operation costs

Huilian's high-quality seals, chisels, pistons, and wear parts further ensure smooth operation and optimal protection for your hydraulic systems.

The Risks of Oversizing or Undersizing

Undersized hammers may lead to:

- Increased working time and fuel costs

- Premature hammer wear or failure

Oversized hammers can cause:

- Excavator instability and carrier damage

- Risk of structural failure or accidents

- Increased maintenance due to excessive vibration

Proper sizing is not only a technical issue but a matter of long-term ROI and safety.

Huilian’s Comprehensive Solutions for Hydraulic Hammers

As a global OEM supplier, Guangzhou Huilian Machinery Co., Ltd. provides a complete solution for hydraulic breaker hammers, including original and aftermarket chisels, seal kits, pistons, diaphragms, wear bushes, retainer bars, side bolts, and more. With a strong R&D, QC, and after-sales team, we not only ensure the right product fit but also support long-term operation for our partners and end users worldwide.

How to Request Sizing Support from Huilian

Huilian's sales and technical experts are available to guide you through the selection process. Provide details about your excavator model, hydraulic specifications, and intended applications. Our team will recommend the ideal hammer size and compatible spare parts, ensuring performance, longevity, and peace of mind.

Maintenance Tips for Your Hydraulic Hammer

Even a perfectly sized hydraulic hammer requires regular maintenance to remain in optimal working condition. Huilian offers OEM-quality spares, including seals and bushings, to ensure minimal downtime and maximum productivity. Regular inspection and timely replacement of wear parts are essential for preserving your investment.

FAQs

What happens if my hydraulic hammer is too heavy for my excavator?

If your hammer is too heavy, it can destabilize the excavator, cause structural damage, and increase the risk of accidents. Always choose a breaker within your machine’s recommended range.

How often should I maintain my hydraulic hammer?

Routine daily inspection is recommended, with more in-depth checks weekly or monthly depending on usage intensity. Replace worn parts promptly to prevent major failures.

Can Huilian assist with custom hydraulic hammer sizing?

Yes! Huilian’s experienced technical and design teams provide tailored recommendations based on your specific equipment and application needs.

Do I need to consider my carrier’s hydraulic flow when sizing a breaker?

Absolutely. Insufficient flow means your hammer may not work efficiently, while excessive flow can cause overheating and premature wear.

What spare parts does Huilian offer for hydraulic hammers?

Huilian provides a full range, including chisels, pipelines, seal kits, pistons, diaphragms, retainer bars, side bolts, through bolts, valves, and liners for most major brands.

How do I become a distributor partner with Huilian?

Contact our sales team through the Huilian website. We seek global partners to promote sustainable excavator parts development.

Choosing the right size hydraulic hammer is fundamental for safe, efficient, and cost-effective operation. By following the sizing guidelines outlined above and leveraging Huilian’s industry-leading expertise and support, you can ensure your hammer and excavator work together flawlessly. We are committed to delivering high-quality products and professional guidance to customers in over 90 countries. For more information or tailored sizing support, contact Huilian today and build a stronger future for your business.

Wholesale hydraulic breaker hammer attachment manufacturer and supplier

Wholesale Kwanglim hydraulic breaker manufacturer and supplier in China

Top 10 Excavator Hydraulic Breaker Manufacturers and Supplier Brands

Top hydraulic breaker hammer Manufacturers and Suppliers in China

About

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

D41101 D41122 D41123 D41124 D41125 Soosan SB45 Hydraulic Rock Hammer Breaker Tool Bits Chisel

Huilian’s Soosan SB45 Hydraulic Rock Hammer Breaker Tool Bits include models D41101, D41122, D41123, D41124, and D41125. Designed for durability and precision, these SB45 chisels and breaker chisels deliver optimal performance in heavy-duty rock breaking and demolition tasks.

C31211 C31212 C31214 C31213 C31215 SOOSAN SB81A SB81 Hydraulic Breaker Hammer Parts Chisel Tool Bits

Huilian Moil Point Wedge Blunt Cone Type Chisel bits for SOOSAN SB81/SB81A hydraulic breaker (C31211-C31215). Durable demolition tool bits engineered for high-impact performance and long wear life. Compatible replacement for SB81 chisel, SB81A chisel - you can order now, we have in stock.

L01118 L01119 L01121 L01122 L01120 SOOSAN SB70 SB81N Chisel Tool Bits for Hydraulic Breaker Hammer

Huilian SOOSAN SB70 SB81N moil-point, wedge, blunt and cone chisel demolition tool bits for hydraulic breaker hammers (L01118, L01119, L01121, L01120, L01122). Heat-treated, wear-resistant steel for reliable demolition performance. Ideal SB70 chisel, SB70 tool and SB70 breaker chisel replacements.

SOOSAN SB60 C21114 C21127 C21128 C21129 C21130 Hydraulic Breaker Hammer Parts Chisel Tool Bits

Huilian SOOSAN SB60 moil point, wedge, blunt and cone chisels — durable demolition rod tool bits for hydraulic breaker hammers (C21114/C21127/C21129/C21128/C21130). High wear resistance, OEM fit for SB60 chisel, SOOSAN SB60, SB60 hydraulic hammer tool.

© 2025 HUILIAN MACHINE. All rights reserved