OEM vs Aftermarket Excavator Breaker Parts: Pros and Cons

- OEM vs Aftermarket Excavator Breaker Parts: Pros and Cons

- Understanding excavator breaker parts and why the choice matters

- What defines OEM excavator breaker parts?

- What are aftermarket excavator breaker parts?

- Side-by-side comparison: OEM vs Aftermarket excavator breaker parts

- Cost vs total cost of ownership for excavator breaker parts

- Performance and safety implications of using aftermarket components

- Warranty, service, and supplier reliability for excavator breaker parts

- When aftermarket parts make strategic sense

- When OEM parts are the safer bet

- Practical procurement checklist for excavator breaker parts

- Why choose Huilian for excavator breaker parts

- How Huilian supports quality verification and service

- Decision guidance: selecting between OEM and aftermarket excavator breaker parts

- FAQ — Common questions about excavator breaker parts

- Contact and call-to-action

- Sources

OEM vs Aftermarket Excavator Breaker Parts: Pros and Cons

Understanding excavator breaker parts and why the choice matters

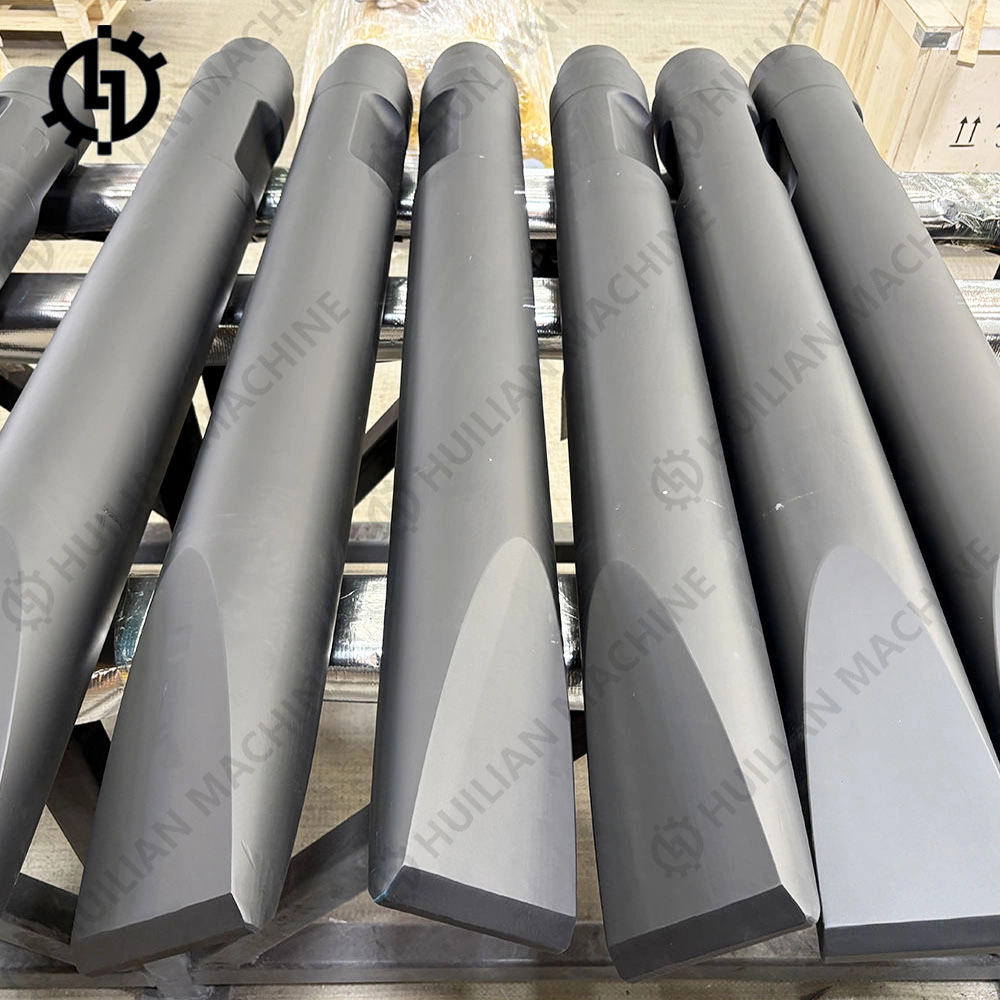

Excavator breaker parts are critical components in construction, demolition and quarrying operations. Whether you operate hydraulic breakers daily or occasionally, the quality and compatibility of replacement parts — chisels, pistons, seals, wear bushes, valves and liners — directly affect machine uptime, safety and total operating cost. Choosing between OEM (Original Equipment Manufacturer) and aftermarket excavator breaker parts is not simply a procurement preference; it is a strategic decision that impacts reliability, repair frequency and resale value.

This article helps fleet managers, maintenance supervisors and purchasing professionals evaluate the pros and cons of OEM vs aftermarket excavator breaker parts so you can make an informed choice for your operation.

What defines OEM excavator breaker parts?

OEM excavator breaker parts are made by the original equipment manufacturer or an approved supplier to the exact specifications used when the breaker was built. The main advantages of OEM parts typically include guaranteed fit, documented material and dimensional conformity, and often a manufacturer-backed warranty that aligns with the machine’s service specifications.

Key attributes of OEM parts:

- Exact dimensional match to original designs

- Material and heat-treatment processes specified by the machine maker

- Product documentation and traceability

- Compatibility assurances across model ranges

For operators who prioritize predictable performance and worry-free installation, OEM excavator breaker parts minimize the risk of compatibility issues and unexpected downtime during service.

What are aftermarket excavator breaker parts?

Aftermarket parts are produced by third-party manufacturers who are not the original equipment maker. A spectrum exists within the aftermarket: from budget-grade replicas to high-quality alternatives engineered to equal or improve on OEM performance. Aftermarket suppliers often compete on price, availability and the ability to serve a broad range of brands and models.

Attributes of aftermarket parts:

- Wider price range, often lower-cost options

- Availability for older or discontinued models

- Potential for design improvements or alternative materials

- Variable quality — from excellent to poor, depending on the manufacturer

Choosing aftermarket excavator breaker parts requires careful supplier selection and quality verification (e.g., material certificates, dimensional checks, sample testing).

Side-by-side comparison: OEM vs Aftermarket excavator breaker parts

Below is a concise table comparing common factors that matter when buying excavator breaker parts. Ratings are generalizations that may vary by brand and supplier.

| Factor | OEM Parts | Aftermarket Parts | Notes / Typical Source |

|---|---|---|---|

| Fit & Compatibility | High | Medium (can be High with reputable suppliers) | OEM designs ensure direct interchangeability |

| Quality Consistency | High | Variable | Aftermarket varies by manufacturer QC processes |

| Cost | Higher | Lower to comparable | Aftermarket often offers price savings |

| Availability | Good for current models, limited for discontinued | Often better for older/discontinued models | Aftermarket can stock hard-to-find parts |

| Warranty & Support | Strong (OEM-backed) | Varies by supplier | Check warranty terms and returns policy |

| Long-term Value | Often better due to uptime & resale | Can be better if quality is high & cost is lower | Consider total cost of ownership |

Sources for comparison: industry reviews and supplier quality reports (see source list at article end).

Cost vs total cost of ownership for excavator breaker parts

Upfront cost is usually the first consideration. Aftermarket parts often save money initially — sometimes 20–50% lower than OEM — but the overall value depends on lifespan, failure rates and downtime costs. When a cheaper chisel or seal fails early and causes secondary damage (e.g., piston scoring, valve failure), the cumulative repair and downtime cost can outweigh initial savings.

How to evaluate total cost:

- Track mean time between failures (MTBF) for replacement parts.

- Include labor and crane/down-time costs for each replacement event.

- Consider potential collateral damage caused by inferior parts.

Recommendation: For mission-critical breakers or high-utilization fleets, prioritize parts with proven lifespan data and warranties. For low-usage equipment or legacy machines where OEM parts are discontinued, vetted aftermarket options can be cost-effective.

Performance and safety implications of using aftermarket components

Performance is not solely a function of the brand label. High-quality aftermarket vendors design parts that meet or exceed OEM specifications, using similar materials and heat treatment processes. However, lower-quality aftermarket components can compromise energy transfer efficiency, accelerate wear, and increase the risk of in-service failure — a safety concern in demolition settings.

What to check when assessing aftermarket performance:

- Material certificates (e.g., steel grade, hardness testing)

- Dimensional tolerance reports

- Surface treatment and coating specifications

- Customer references and field test data

If safety and controlled performance are priorities on your sites, demand proof of quality from aftermarket suppliers before adoption.

Warranty, service, and supplier reliability for excavator breaker parts

OEM parts often come with well-defined warranty terms and the support network of authorized dealers. Aftermarket warranties vary — some manufacturers offer competitive warranty coverage, while others provide limited or no warranty.

When choosing a supplier, whether OEM or aftermarket, evaluate:

- Warranty duration and coverage terms

- Return and RMA policies

- Availability of technical support and installation guidance

- Spare parts availability and lead times

Supplier reliability directly affects operational continuity. Prefer suppliers with traceable manufacturing standards, QC documentation and post-sale service teams.

When aftermarket parts make strategic sense

Aftermarket excavator breaker parts can be the better choice in several scenarios:

- Older or discontinued breaker models where OEM parts are unavailable or take long lead times.

- Cost-sensitive operations where validated aftermarket components provide acceptable lifecycle performance.

- Situations where aftermarket vendors offer design improvements (e.g., enhanced chisels, longer-life wear bushes).

Best practice: test aftermarket parts on a single machine or non-critical job before fleet-wide adoption, and track performance metrics over time.

When OEM parts are the safer bet

OEM excavator breaker parts are advisable when:

- Machines operate in high-risk or safety-sensitive environments.

- You require guaranteed fit and minimal installation troubleshooting.

- There is significant resale value tied to maintaining OEM service records.

OEM parts are also preferred for warranty-preservation on some new machines; check manufacturer policies to avoid voiding machine warranties.

Practical procurement checklist for excavator breaker parts

Use this checklist to make consistent purchasing decisions:

- Confirm exact part number and compatibility with your breaker model.

- Request material and heat-treatment certificates for critical components (pistons, chisels, pins).

- Ask for dimensional tolerance reports and sample validation for aftermarket suppliers.

- Compare warranty terms and return conditions.

- Assess supplier lead times and on-site support availability.

- Pilot aftermarket parts before fleet-wide rollouts.

Document results in your maintenance management system so you can measure MTBF and cost per operating hour for each part type.

Why choose Huilian for excavator breaker parts

Founded in 2005, Huilian Machine is a professional OEM supplier of excavator parts. We are leading excavator breaker parts manufacturers from China with a comprehensive product range and global experience. Huilian offers hydraulic breaker hammers, chisels, seals and seal kits, diaphragms, pistons, WearBush, rompin/retainer bars, through bolts, side bolts, valves and liners — covering the full spectrum of excavator breaker parts.

Huilian's competitive strengths:

- Experienced team: technicians, R&D experts, designers, quality control professionals, sales and after-sales teams committed to product reliability.

- Quality management: production processes aimed at consistent material properties and dimensional accuracy, supporting both OEM and high-quality aftermarket demands.

- Global footprint: products exported to over 90 countries and regions with strong customer recognition for quality and variety.

- Partnership focus: Guangzhou Huilian Machinery Co., Ltd. seeks global distributor partners to promote sustainable industry development.

For fleet operators evaluating OEM vs aftermarket excavator breaker parts, Huilian provides a balanced solution: OEM-grade manufacturing discipline with aftermarket flexibility and competitive pricing. Whether you need a certified seal kit for a recent model or a hard-to-find retainer bar for an older breaker, Huilian can support your parts strategy and help optimize total cost of ownership.

Visit Huilian's website for product details: https://www.huilianmachine.com/

How Huilian supports quality verification and service

Huilian provides documentation and test data on request, including material certifications, dimensional checks and sample testing. They offer technical support for part selection and installation, and can assist distributors with local aftermarket stocking strategies. This helps buyers confidently select parts that meet performance and safety expectations.

Decision guidance: selecting between OEM and aftermarket excavator breaker parts

A pragmatic decision framework:

- Define criticality: Is the breaker critical to continuous operation? If yes, favor proven OEM or highly vetted aftermarket parts.

- Gather data: Use historical MTBF and repair cost data to inform choices.

- Pilot and measure: Test new aftermarket parts on low-risk machines and record performance.

- Negotiate warranty and support: Ensure clear coverage before buying.

- Optimize mix: Use OEMs where risk is high and vetted aftermarket parts where cost savings and adequate performance are proven.

This mixed strategy often delivers the best balance of uptime, cost control and long-term value.

FAQ — Common questions about excavator breaker parts

Q: Are aftermarket excavator breaker parts always inferior to OEM?

A: No. The aftermarket includes both low-quality copies and highly reputable manufacturers that produce parts meeting or exceeding OEM specifications. Vet suppliers via certifications, test data and references.

Q: Will using aftermarket parts void my machine warranty?

A: It depends on the terms of your machine warranty. Some OEM warranties are specific about parts and authorized service; others allow aftermarket parts but may limit coverage on components affected by third-party parts. Always check your warranty policy.

Q: How can I verify the quality of aftermarket chisels and pistons?

A: Request material certificates, hardness test reports, dimensional inspection reports and, if possible, field test results or sample parts for validation. Reputable suppliers will provide documentation and references.

Q: Is it worth stocking aftermarket parts in-house?

A: Yes, for common wear items like seal kits, chisels and bolts. Stocking reduces downtime. Prioritize parts based on failure frequency and lead times. Maintain traceability of the supplier used so you can correlate part performance over time.

Q: Where can I buy reliable aftermarket excavator breaker parts?

A: Look for established suppliers with OEM manufacturing experience, transparent QC documentation and global references. Huilian Machine (founded 2005) is one such supplier that offers a broad product portfolio and export experience to over 90 countries.

Contact and call-to-action

If you need help comparing OEM vs aftermarket excavator breaker parts for your fleet, or want technical documentation and sample quotes, contact Huilian’s sales team or view their product catalog: https://www.huilianmachine.com/

Request product specifications, material certificates and warranty terms before making bulk purchases. Proper verification reduces risk and improves long-term value.

Sources

- Industry technical articles and buyer guides from Construction Equipment and ForConstructionPros on OEM vs aftermarket parts (industry publications covering heavy equipment maintenance practices).

- Association of Equipment Manufacturers (AEM) guidance on parts and service best practices.

- Huilian Machine company data and product information (company-provided specifications and export summary).

- ISO 9001 quality management principles as a baseline for supplier evaluation.

(For source details and independent verification, consult the listed industry publications and supplier documentation.)

Top 10 hydraulic breaker Manufacturers and Supplier Brands in 2026

Rebuilding Hydraulic Breakers: Parts and Cost Guide

Wholesale Sandvik hydraulic breaker manufacturer and supplier in China

Wholesale MTB hydraulic breaker manufacturer and supplier in China

About

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

C31211 C31212 C31214 C31213 C31215 SOOSAN SB81A SB81 Hydraulic Breaker Hammer Parts Chisel Tool Bits

Huilian Moil Point Wedge Blunt Cone Type Chisel bits for SOOSAN SB81/SB81A hydraulic breaker (C31211-C31215). Durable demolition tool bits engineered for high-impact performance and long wear life. Compatible replacement for SB81 chisel, SB81A chisel - you can order now, we have in stock.

Soosan SB43 Hydraulic Rock Hammer Tool 75mm Cr42 F91144 F91145 F91146 F91147 F91148 Hydraulic Breaker Parts Moil Point Wedge Blunt Cone Type Chisel

The Huilian Soosan SB43 Hydraulic Rock Hammer Tool—featuring 75mm Cr42 steel—is compatible with F91144 to F91148 breakers. Ideal for SB43 chisel and SB43 breaker tool users, this durable hydraulic breaker part includes moil point, wedge, blunt, and cone-type chisels for versatile rock breaking applications.

D41101 D41122 D41123 D41124 D41125 Soosan SB45 Hydraulic Rock Hammer Breaker Tool Bits Chisel

Huilian’s Soosan SB45 Hydraulic Rock Hammer Breaker Tool Bits include models D41101, D41122, D41123, D41124, and D41125. Designed for durability and precision, these SB45 chisels and breaker chisels deliver optimal performance in heavy-duty rock breaking and demolition tasks.

L01118 L01119 L01121 L01122 L01120 SOOSAN SB70 SB81N Chisel Tool Bits for Hydraulic Breaker Hammer

Huilian SOOSAN SB70 SB81N moil-point, wedge, blunt and cone chisel demolition tool bits for hydraulic breaker hammers (L01118, L01119, L01121, L01120, L01122). Heat-treated, wear-resistant steel for reliable demolition performance. Ideal SB70 chisel, SB70 tool and SB70 breaker chisel replacements.

© 2025 HUILIAN MACHINE. All rights reserved