Bulk Procurement Strategies for Hydraulic Breaker Chisel Parts

- Bulk Procurement Strategies for Hydraulic Breaker Chisel Parts

- Understanding Hydraulic Breaker Chisel Parts and why bulk procurement matters

- Product highlight: Cr42 155mm Chisel Soosan SB121 Hydraulic Breaker Parts

- How bulk procurement aligns with for Hydraulic Breaker Chisel Parts

- Demand forecasting and inventory planning for Hydraulic Breaker Chisel Parts

- Supplier selection and qualification for Hydraulic Breaker Chisel Parts

- Quality assurance and testing protocols for chisel parts

- Table: Comparative metrics — Single purchase vs Bulk purchase vs Consignment for Hydraulic Breaker Chisel Parts

- Pricing strategy, negotiation and contract terms

- Logistics, packaging, and storage best practices for chisel parts

- Cost-benefit analysis and ROI of bulk procurement

- Brand advantages: Why choose Huilian's Cr42 155mm Chisel for Soosan SB121

- Implementation checklist and timeline for bulk procurement

- Risk mitigation, warranties, and aftermarket support

- Frequently Asked Questions (FAQ) — Hydraulic Breaker Chisel Parts & Bulk Procurement

- Contact us / View product

- Authoritative references

Bulk Procurement Strategies for Hydraulic Breaker Chisel Parts

Understanding Hydraulic Breaker Chisel Parts and why bulk procurement matters

Hydraulic Breaker Chisel Parts are critical wear components for excavator-mounted breakers used in demolition, quarrying, roadwork, and foundation construction. Procuring these parts in bulk reduces unit cost, shortens repair turnaround through stocked spares, and minimizes machine downtime. For heavy-duty applications, choosing the right chisel material, heat treatment, and compatible sizes is essential to maximize service life and productivity.

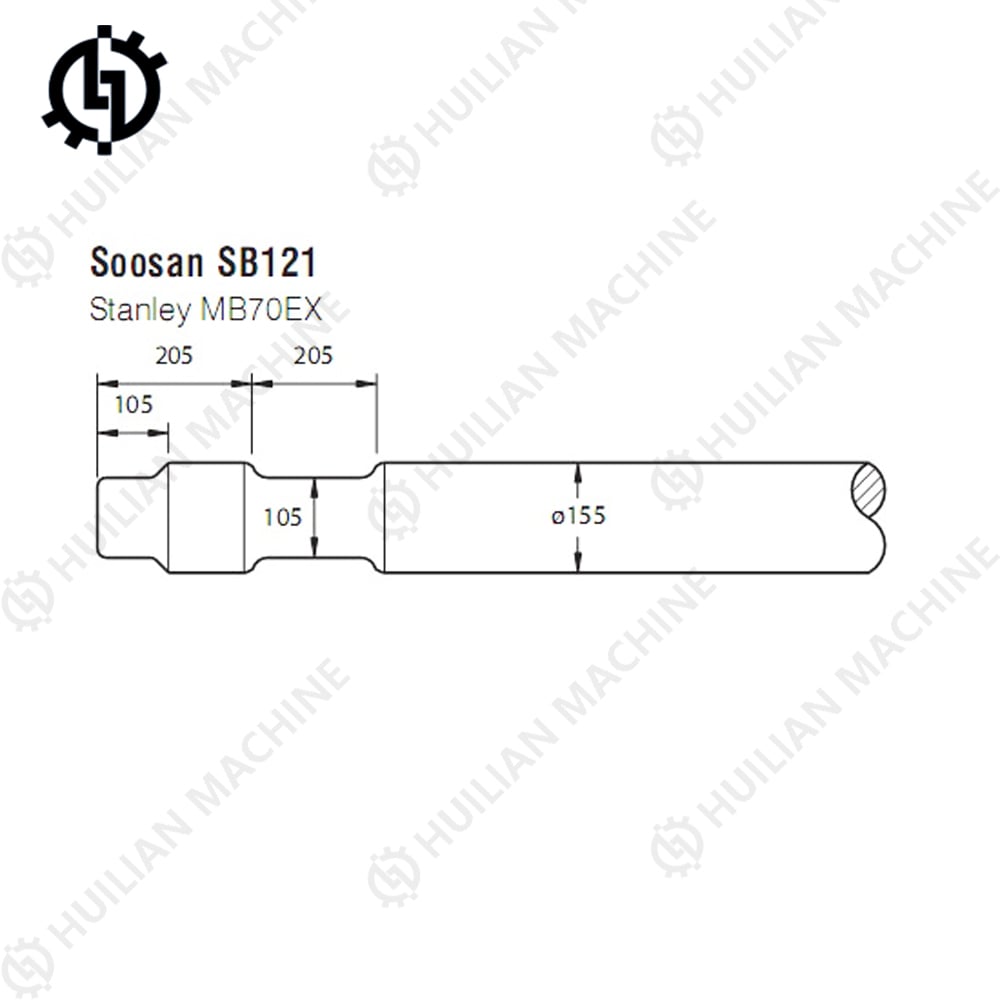

Product highlight: Cr42 155mm Chisel Soosan SB121 Hydraulic Breaker Parts

Huilian’s Cr42 155mm SB121 chisel delivers superior durability for Soosan SB121 hydraulic breakers. Compatible with parts C61227, C61228, C61229, C61230, and C61231, this rock hammer tool enhances performance with moil point, wedge, blunt cone, and rod bit options.

How bulk procurement aligns with for Hydraulic Breaker Chisel Parts

Organizations buying Hydraulic Breaker Chisel Parts in volume—rental fleets, contractors, and OEM spare departments—seek lower total cost of ownership (TCO), predictable supply, and consistent performance. Bulk procurement meets these needs by enabling better pricing structures, prioritized manufacturing slots, and supplier-backed technical support. This section explains the commercial benefits and the practical levers buyers can pull to achieve them.

Demand forecasting and inventory planning for Hydraulic Breaker Chisel Parts

Accurate demand forecasting is the foundation of any bulk procurement strategy. Start with equipment fleet records: breaker model, average operating hours, typical chisel type used (moil point, wedge, blunt cone, rod bit), and historical replacement intervals. For example, a busy urban demolition fleet may consume chisels 30–50% faster than a rural quarry operation.

- Establish baseline consumption: record parts replaced per breaker per year.

- Segment by chisel type: moil point vs wedge vs blunt cone vs rod bits—each wears differently.

- Factor in seasonality and project cycles: high-intensity projects require buffer stock.

- Set service level targets: e.g., 98% availability for critical projects.

Use simple reorder point formulas or inventory software to translate forecasts into order quantities and timing. When buying Hydraulic Breaker Chisel Parts in bulk, the reorder policy should balance holding costs with stockout risk and consider lead times from the supplier.

Supplier selection and qualification for Hydraulic Breaker Chisel Parts

Choosing a reliable supplier is more important than the nominal per-unit price. Qualification should include technical capability, manufacturing consistency, certification (e.g., ISO 9001), and references from customers using the same chisel types and breaker models.

Key supplier evaluation criteria:

- Compatibility assurance: stamped or machined dimensions that match Soosan SB121 reference parts C61227–C61231.

- Material traceability: Cr42 grade specification and heat-treatment process documentation.

- Quality control: hardness testing (HB/HRC), impact toughness, and nondestructive testing where applicable.

- Capacity and lead time stability: ability to scale orders and maintain delivery schedules.

- After-sales support: replacement guarantees, technical advice, and refurbishment options.

Include on-site audits or sample testing in the qualification process before awarding large-volume contracts for Hydraulic Breaker Chisel Parts.

Quality assurance and testing protocols for chisel parts

High-volume purchases require a defined quality assurance (QA) protocol to prevent costly failures in the field. QA steps should include batch sampling, metallurgical verification, dimensional inspection, and, where possible, field validation trials on representative equipment.

- Incoming inspection: measure length, diameter, tip geometry, and surface treatment.

- Material checks: verify Cr42 chemistry, hardness profile, and microstructure.

- Functional testing: pilot-run attachments on a subset of breakers to observe wear behavior.

- Acceptance criteria: define allowable tolerances and rejection rates (e.g., <1% critical defects).

Document QA results and maintain traceability for each batch of Hydraulic Breaker Chisel Parts to enable root-cause analysis if failures occur.

Table: Comparative metrics — Single purchase vs Bulk purchase vs Consignment for Hydraulic Breaker Chisel Parts

| Metric | Single Purchase | Bulk Purchase | Consignment |

|---|---|---|---|

| Unit Price | Highest | Lower (10–30% discount) | Variable (often similar to bulk) |

| Lead Time | Standard | Longer for large runs, but planned | Fast access, supplier retains inventory |

| Inventory Holding Cost | Low | High | Low for buyer, high for supplier |

| Stockout Risk | Higher | Lower | Lowest |

| Quality Consistency | Variable | Better if supplier controlled | Good with SLA |

Pricing strategy, negotiation and contract terms

When negotiating bulk contracts for Hydraulic Breaker Chisel Parts, structure terms to capture savings while protecting operational flexibility.

Recommended contract clauses:

- Tiered pricing: defined price breaks at specific volumes.

- Minimum order quantities (MOQs) and delivery phasing to align with storage capacity.

- Quality warranty: specify replacement terms for defective batches and acceptable failure rates.

- Lead-time guarantees: penalties or expedited options for missed SLAs.

- Option to scale: short-term price reviews for large scale-ups or scope changes.

Use total cost analysis rather than per-unit price alone: include freight, customs, holding costs, and expected downtime cost avoided by having parts on hand.

Logistics, packaging, and storage best practices for chisel parts

Proper logistics and storage preserve part integrity. Chisels are often shipped in bundles, on pallets, or in protective sleeves. Bulk buyers should define packaging specs to avoid corrosion, deformation, or contact damage.

- Rust prevention: oil coatings, VCI paper, or sealed plastic sleeves for long storage.

- Storage conditions: dry, temperate environment; upright racking for long chisels to avoid bending.

- Labeling and traceability: batch numbers and compatibility codes (e.g., Soosan SB121 C61227 etc.).

- Inbound receipt process: visual inspection, match to PO, update inventory management system.

Cost-benefit analysis and ROI of bulk procurement

Calculate ROI by comparing discounted purchase costs and avoided downtime against increased inventory carrying costs. Typical ROI drivers:

- Discount per unit from supplier for committed volumes.

- Downtime cost avoided by immediate availability: often the largest hidden saving.

- Reduced administrative costs from fewer purchase orders and supplier interactions.

Example simple calculation: if one chisel failure causes a 4-hour machine downtime valued at $1,200 productivity loss, preventing 5 such events yearly by having spares yields $6,000 savings. If bulk ordering reduces annual parts spend by $4,000, the net annual benefit is $10,000 minus added holding costs.

Brand advantages: Why choose Huilian's Cr42 155mm Chisel for Soosan SB121

When evaluating Hydraulic Breaker Chisel Parts, Huilian's Cr42 155mm SB121 chisel offers specific advantages relevant to bulk buyers:

- Compatibility: designed to fit Soosan SB121 reference parts C61227–C61231, reducing fitment risk across common chisel variants.

- Material grade: Cr42 specification provides a balance between hardness and toughness for prolonged life in rock and concrete applications.

- Multiple tip geometries: moil point, wedge, blunt cone, and rod bits allow optimization by application without changing shank size.

- Manufacturing consistency: batch testing and traceability reduce field failure rates when part of a qualified supply program.

For buyers, these attributes mean easier stocking decisions, reduced SKU proliferation, and predictable field performance—key elements when negotiating bulk purchase agreements.

Implementation checklist and timeline for bulk procurement

Use this phased checklist to implement a bulk procurement program for Hydraulic Breaker Chisel Parts over 8–12 weeks.

- Weeks 1–2: Data collection – fleet usage, failure rates, preferred chisel types.

- Weeks 2–4: Supplier shortlisting and sample ordering for QA tests.

- Weeks 4–6: Sample testing (dimensional, material, field trial).

- Weeks 6–8: Negotiate contract terms, MOQs, pricing tiers, and warranty clauses.

- Weeks 8–10: Finalize packaging and logistics specifications; set up inbound inspection procedures.

- Weeks 10–12: First bulk shipment, update inventory system, train maintenance staff on part IDs and storage protocols.

Risk mitigation, warranties, and aftermarket support

Manage procurement risk by negotiating warranties, clear rejection criteria, and service-level agreements (SLAs) for replacements. Consider a pilot consignment program where the supplier retains ownership of stock until parts are consumed; this can dramatically reduce buyer inventory risk while providing immediate access to spares.

Also clarify responsibilities for transport damage, defective batches, and accelerated delivery options for emergency needs. Maintain documented communication channels for technical support and escalation to ensure fast resolution when issues arise.

Frequently Asked Questions (FAQ) — Hydraulic Breaker Chisel Parts & Bulk Procurement

Q: How do I know the Cr42 155mm chisel fits my Soosan SB121 breaker?

A: Compatibility is verified against the OEM reference parts C61227–C61231. Confirm shank diameter and seating dimensions match your breaker tool holder. Request dimensional drawings or a sample before placing a bulk order.

Q: What are the expected wear life differences between moil point, wedge, and blunt cone chisels?

A: Moil points are general-purpose and provide concentrated impact—good for breaking concrete. Wedges split material and are efficient in layered rock. Blunt cones are more durable for heavy-duty rock chiseling but remove material slower. Actual life varies with material, operator technique, and breaker energy. Conduct a short field trial to establish local wear rates.

Q: How much inventory should I hold when switching to bulk procurement?

A: Size inventory based on average consumption and supplier lead times. A typical rule is 1.5–3 months of usage for critical parts, adjusted for supply reliability and project criticality.

Q: What quality certificates should I request from a chisel manufacturer?

A: Request material certificates showing Cr42 chemistry, heat-treatment reports, and ISO 9001 certification for the manufacturing facility. Hardness test results and batch traceability are also advised.

Q: Can bulk procurement lock me into outdated part specifications?

A: Include flexibility clauses in contracts for design updates and allow periodic reviews. Use phased deliveries to avoid obsolete stock during multi-year contracts.

Contact us / View product

To discuss bulk pricing, sample orders, or technical compatibility for Huilian's Cr42 155mm Chisel Soosan SB121 Hydraulic Breaker Parts (C61227–C61231), contact our sales team or request a product datasheet. We provide competitive bulk terms, QA documentation, and logistics support to ensure a smooth procurement rollout.

Authoritative references

- Hydraulic breaker (Wikipedia) — https://en.wikipedia.org/wiki/Hydraulic_breaker

- Soosan Hydraulic Breakers (manufacturer reference) — https://www.soosan.com

- ISO 9001 Quality Management Systems overview — https://www.iso.org/iso-9001-quality-management.

- Materials and heat treatment basics (ASM International) — https://www.asminternational.org

How to Charge a Hydraulic Breaker – Expert Guide (Huilian)

How Seal Kit Quality Affects Excavator Downtime and ROI

Top hydraulic seal kits Manufacturers and Suppliers in China

Top Excavator Hydraulic Breaker Manufacturers and Suppliers in China

About

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

Huilian OEM Hydraulic Rock Breaker HB40G For FURUKAWA

C71429 SU+165 TR-F SU+165TRF SU165 SU+165 Seal Kit SU+155 Oil Repair Kit For Excavator Attachment SOOSAN Hydraulic Rock Breaker Hammer Spare Part

Huilian OEM Excavator Hydraulic Cylinder Seal Kit 199-7416 For Caterpillar

Introducing the Huilian OEM Excavator Hydraulic Cylinder Seal Kit 199-7416, designed specifically for Caterpillar machinery. Ensure optimal performance and longevity with our premium Cylinder Seal Kit, crafted for durability and precision. Trust Huilian for reliable, top-quality solutions in hydraulic maintenance. Enhance your equipment's efficiency today!

OEM Excavator Spare parts PC2000-8 Track Adjuster Seal Kit For Komatsu

Huilian OEM Excavator Spare Parts PC2000-8 Track Adjuster Seal Kit for Komatsu. Ensures optimal track adjustment performance. High-quality replacement for your PC2000-8 excavator. Order your kit today!

© 2025 HUILIAN MACHINE. All rights reserved