How to Choose the Right 68mm Hydraulic Rock Breaker Chisel

- Selecting the Correct Chisel for Your Hydraulic Rock Breaker

- Understand chisel sizing and shank compatibility

- Match chisel type to job application

- Check OEM part numbers and cross-compatibility

- Material, Hardness and Manufacturing: Why Cr42 Matters

- What is Cr42 and why it is used?

- Hardness vs. toughness: selecting the right balance

- Manufacturing quality indicators to look for

- Comparing Chisel Tip Types — Use Cases and Wear Characteristics

- Chisel profile comparison table

- How to choose based on material and job type

- Expected wear rates and lifecycle planning

- Installation, Maintenance and Troubleshooting

- Proper installation and fitment

- Routine maintenance tips to extend service life

- Troubleshooting common problems

- Cost, Warranty and OEM vs. Aftermarket Considerations

- Price vs. lifecycle cost analysis

- OEM parts vs. high-quality aftermarket

- Warranty and supplier reliability

- Product Spotlight and Brand Advantages

- How this product family aligns with selection criteria

- Brand strengths and practical benefits

- When to choose this product

- Practical Purchase Checklist

- FAQ — Frequently Asked Questions

- Q: Is 68mm a standard shank size for Soosan SB40?

- Q: How often should I replace a hydraulic breaker chisel?

- Q: Can I use harder steel for longer life?

- Q: How to avoid chisel loosening during operation?

- Q: Are aftermarket chisels reliable?

- Contact / View Product

- Authoritative References

Choosing the correct Hydraulic Rock Breaker chisel determines the efficiency, lifespan, and safety of demolition and rock excavation jobs. This guide explains how to select a 68mm chisel (shank), compares chisel types—moil point, wedge, blunt and cone—discusses Cr42 material advantages, and provides practical tips for installation, maintenance and troubleshooting. It is written for equipment owners, fleet managers and maintenance technicians seeking clear, actionable advice on hydraulic hammer parts and breaker chisel selection.

Selecting the Correct Chisel for Your Hydraulic Rock Breaker

Understand chisel sizing and shank compatibility

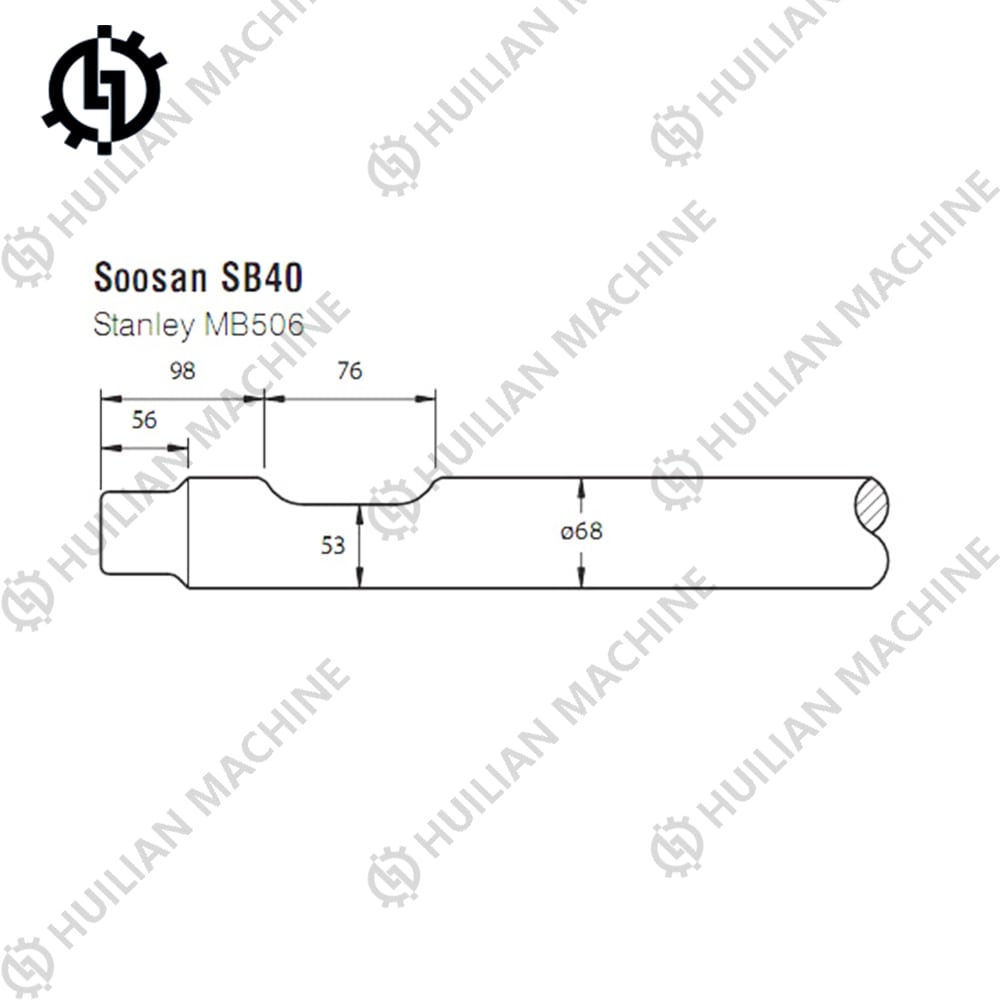

One of the first checks when choosing a Hydraulic Rock Breaker chisel is the shank diameter and length. Many breaker models—including popular carrier-mount hammers—use a standardized shank size (commonly described as 68mm in some markets). Confirm your hammer model (for example, Soosan SB40) and the specified shank diameter in the breaker manual before ordering a replacement chisel. Incorrect shank fit causes excessive play, accelerated wear, and potential hammer damage.

Match chisel type to job application

Different chisel tip profiles are optimized for specific tasks. The main types are moil point, wedge, blunt, and cone chisel. Choose a chisel profile based on material hardness, desired fragmentation size, and carrier machine power to maximize productivity.

Check OEM part numbers and cross-compatibility

Always verify OEM part numbers or approved aftermarket equivalents. The product family name 68mm Tool Chisel Cr42 Soosan SB40 Hydraulic Rock Breaker C01220 C01221 C01222 C01223 C01224 identifies a range of tip profiles for the same shank and breaker model. When possible, match the OEM code or consult technical cross-reference charts to ensure proper fit and warranty compliance.

Material, Hardness and Manufacturing: Why Cr42 Matters

What is Cr42 and why it is used?

Cr42 denotes a chromium-alloyed steel grade used in many hammer tool steels for a balance of toughness and wear resistance. Using higher-chromium tool steel improves impact fatigue performance and reduces chipping at the tip. For a technical overview of hydraulic breaker systems and material considerations, see Hydraulic breaker (Wikipedia) and for chromium steels see Chromium steel (Wikipedia). Quality heat treatment and controlled forging during manufacturing are as critical as alloy chemistry; they determine hardness, core ductility and service life.

Hardness vs. toughness: selecting the right balance

Chisels require a balance between surface hardness (for wear resistance) and core toughness (to avoid brittle failure). Typical tool steels for breaker chisels are hardened at the tip (higher HRC) while maintaining a tougher shank core. For field use, a chisel with appropriate hardness and a well-controlled heat-treat provides longer wear life without frequent breakage.

Manufacturing quality indicators to look for

Inspect for consistent heat-treatment markings, clean machining, accurate shank tolerances and full-length carburized or induction-hardened tips (depending on design). Reputable manufacturers provide traceable batch data and material certificates for Cr42 or equivalent grades. These quality controls reduce the risk of premature chisel failure and inconsistent performance.

Comparing Chisel Tip Types — Use Cases and Wear Characteristics

Chisel profile comparison table

| Chisel Type | Best for | Advantages | Limitations |

|---|---|---|---|

| Moil Point | General breaking, trenching, demolition | Good penetration, versatile, easy to resharpen | Faster wear on very hard rock |

| Wedge | Splitting rock and concrete, creating controlled breaks | Excellent splitting force, effective in layered materials | Requires more power; not for penetration-only tasks |

| Blunt (Flat) | Recycling, plate breaking, tamping | Distributes force, long tip life on abrasive materials | Poor penetration in very hard rock |

| Cone (Pointed) | Drilling assist, pilot breakthrough, very localized impact | Very focused energy, good for starting fractures | Quick wear on abrasive stone; brittle if over-hardened |

How to choose based on material and job type

- Soft to medium rock and general demolition: choose a moil point for balanced performance and ease of reshaping.

- Layered or blocky rock where split control matters: use a wedge chisel.

- Rebar, metal plates, or high-abrasion recycling: blunt chisel offers longer wear life.

- Precise fracture initiation or pilot holes: cone tips can be effective when used intermittently.

Expected wear rates and lifecycle planning

Wear rates depend on rock abrasivity, hammer energy, operator technique and chisel material. Plan lifecycle by monitoring tip geometry—loss of face radius or excessive shortening indicates replacement. For budgeting, consider mean-time-between-replacements (MTBR) from similar fleet histories and keep a small stock of each chisel type to minimize downtime.

Installation, Maintenance and Troubleshooting

Proper installation and fitment

Before installation, clean the hammer bore and check retaining pins, locking collars and bushings. Insert the chisel ensuring correct orientation and full engagement with the retaining system. Loose retainment or corrosion on the shank causes hammer impact on the wrong surfaces, increasing wear on the tool and breaker components.

Routine maintenance tips to extend service life

- Daily: inspect for looseness, oil leaks, and visible tip damage. Check hydraulic oil cleanliness and pressure per hammer manual.

- Weekly: measure chisel protrusion and check bushing wear; replace worn bushings promptly.

- Monthly: confirm chisel hardness markings and shank diameter for fit; verify retaining pins and set screws torque.

Keeping hydraulic oil clean and using correct oil grade avoids cavitation and blow-by that can damage internal hammer components and reduce chisel effectiveness.

Troubleshooting common problems

- Symptom: Rapid tip wear. Causes: incorrect chisel type, abrasive rock, poor heat treatment. Solution: switch to harder tip or change to blunt profile for abrasive tasks.

- Symptom: Chisel loosening in the tool carrier. Causes: worn bushings or incorrect shank diameter. Solution: replace bushings, verify shank spec (68mm standard) and inspect retaining hardware.

- Symptom: Hammer overheating and loss of power. Causes: hydraulic flow issues, wrong oil viscosity, internal valve faults. Solution: follow hammer manufacturer diagnostics and check oil contamination.

Cost, Warranty and OEM vs. Aftermarket Considerations

Price vs. lifecycle cost analysis

Purchasing decisions should be based on lifecycle cost, not only upfront price. A more expensive Cr42 chisel with correct heat treatment and precise tolerances often reduces downtime, extends replacement intervals, and lowers per-ton breakage cost. When evaluating bids, request wear data or references from similar applications.

OEM parts vs. high-quality aftermarket

OEM (original equipment manufacturer) parts usually guarantee compatibility and come with warranty support. High-quality aftermarket parts may offer cost savings but verify metallurgy, heat treatment records and dimensional accuracy. For the Soosan SB40 breaker, the product family name (for example C01220–C01224) assists in confirming correct aftermarket cross-reference.

Warranty and supplier reliability

Choose suppliers who provide material certificates, positive customer references, and clear replacement policies. Reliable vendors will also offer technical support on chisel selection and post-sale troubleshooting—an important factor when minimizing machine downtime is critical.

Product Spotlight and Brand Advantages

Product Brief:

68mm Tool Chisel Cr42 Soosan SB40 Hydraulic Rock Breaker C01220 C01221 C01222 C01223 C01224 Hydraulic Hammer Parts Moil Point Wedge Blunt Cone Type

The following paragraph is the product introduction provided by the manufacturer:

Huilian 70mm Tool Chisel Cr42 for Soosan SB40 Hydraulic Rock Breaker offers durable, precise performance. Compatible with SB40 chisel and breaker chisel models, this moil point, wedge, blunt, and cone type hammer part ensures optimal hydraulic hammer efficiency and longevity.

How this product family aligns with selection criteria

Although the primary topic of this guide is a 68mm chisel, the Huilian product line includes tool chisels engineered for Soosan SB40 models and similar breakers, offered in multiple tip profiles (moil, wedge, blunt, cone). The inclusion of Cr42 material and multiple OEM cross-reference codes (C01220–C01224) indicate a broad compatibility set and a focus on wear-resistant tool steels.

Brand strengths and practical benefits

Key brand advantages to consider when choosing Huilian or similar suppliers:

- Material transparency: use of Cr42 alloy and (when available) heat-treatment documentation improves confidence in product life.

- Multiple tip types in one family reduce procurement complexity—same family covers moil, wedge, blunt and cone.

- Compatibility data for popular breakers (Soosan SB40) simplifies fitment and reduces risk of ordering mistakes.

- After-sale support and replacement parts availability shorten downtime windows.

When to choose this product

Choose Huilian or an equivalent Cr42 tool chisel when you need a balance of wear resistance and impact toughness for general excavation and demolition on a Soosan SB40-type breaker. If your application involves extremely abrasive material or specialized demolition (e.g., demolition with heavy metal recycling), consider blunt profiles or custom hardened tips and consult supplier test data.

Practical Purchase Checklist

- Confirm hammer model and shank diameter (target: 68mm or the exact spec noted in your hammer manual).

- Identify the working material and choose chisel type (moil/wedge/blunt/cone) accordingly.

- Request material certificates and heat-treatment records for Cr42 or equivalent alloys.

- Check OEM cross-reference codes (C01220–C01224) and compatibility notes for Soosan SB40.

- Verify supplier warranty, lead times and local support for parts and service.

FAQ — Frequently Asked Questions

Q: Is 68mm a standard shank size for Soosan SB40?

A: Shank sizes vary by manufacturer and region. Verify the exact shank diameter and length in your hammer manual or by measuring the existing chisel. The product family names (C01220–C01224) show cross-compatibility; confirm with the supplier for exact fitment to the Soosan SB40.

Q: How often should I replace a hydraulic breaker chisel?

A: Replacement frequency depends on application, rock abrasivity and operator technique. Monitor tip length and face shape—replace when the effective length is significantly reduced or the tip geometry is no longer effective. Typical life ranges from tens to hundreds of hours under different conditions; track MTBR from your fleet to plan stock levels.

Q: Can I use harder steel for longer life?

A: Increasing tip hardness can improve wear resistance but may reduce toughness, risking brittle failure in impact applications. A Cr42-grade chisel, properly heat-treated, aims to balance hardness and toughness. Consult the supplier’s heat-treatment data and consider application-specific recommendations.

Q: How to avoid chisel loosening during operation?

A: Ensure correct shank diameter and bushing fit, regularly inspect and replace worn bushings and retaining pins, and use the correct retention torque and locking system specified by the hammer manufacturer.

Q: Are aftermarket chisels reliable?

A: High-quality aftermarket chisels can be reliable if the manufacturer provides detailed material specifications, heat-treatment records, and demonstrates dimensional accuracy. Choose suppliers with proven references and warranty policies.

Contact / View Product

If you would like expert guidance specific to your fleet or to view the detailed product pages for the 68mm/70mm tool chisel family, contact us: sales@example.com or visit our product page: View 68mm/70mm Tool Chisel Options.

Authoritative References

For more technical background on hydraulic breakers and material selection, see Hydraulic breaker (Wikipedia) and Chromium steel (Wikipedia).

OEM vs Aftermarket Hydraulic Breaker Seal Kits: Pros & Cons

Bulk Buying Tips: Reduce Costs on Wholesale Excavator Breaker Parts

Wholesale excavator hydraulic breaker manufacturer and supplier

Top 10 Excavator Seal Kits for Durable Hydraulics

About

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

SOOSAN L21016 SU+145 TR-F SU+145TRF SU145 SU+145 Seal Kit C61443 SU+125 Oil Repair Kit For Excavator Hydraulic Rock Breaker Hammer Spare Parts

OEM Excavator Spare parts PC2000-8 Track Adjuster Seal Kit For Komatsu

Huilian OEM Excavator Spare Parts PC2000-8 Track Adjuster Seal Kit for Komatsu. Ensures optimal track adjustment performance. High-quality replacement for your PC2000-8 excavator. Order your kit today!

Parker Oil Seal SOOSAN SB45 Hydraulic Rock Hammer Breaker Seal Repair Kit D4X001 D41011 SB45TSP SQ45

Huilian HL68 Hammer Breaker for 4-7 Ton Excavator SOOSAN SB40 Hydraulic Rock Breaker

Side type hydraulic breaker : Easy to control, convenient positioning, durable, high working efficiency, strong striking force, long service life, stable operating performance, convenient after-sales service.

Top type hydraulic breaker : Strong impact power; excellent environmental performance; exquisite manufacturing technology; easy maintenance,fast after-sales service

Box type hydraulic breaker :leading heat treatment technology, enhance heat resistance, wear resistance. Under the condition of keeping the oil pressure constant, the cylinder volumeis reduced and the fuel consumption is reduced.The self-developed core is adopted to make the piston cylinder body moredurable and the service life longer.Exposed decks are made of high-strength steel plates to reduce wear.The best efficiency matching with excavator and loader is realized

© 2025 HUILIAN MACHINE. All rights reserved