Procurement Guide: HB20G Excavator Hydraulic Breaker Furukawa 18-21T

- Procurement Guide: HB20G Excavator Hydraulic Breaker Furukawa 18-21T

- Product Overview: Excavator Hydraulic Rock Breaker Hammer HB20G For Furukawa 18-21 Tons Breaker

- Why choose an excavator hydraulic breaker for Furukawa 18-21t machines

- Key specifications and compatibility

- Performance metrics explained for procurement decisions

- Mounting, hydraulics and installation considerations

- Maintenance, wear parts and service intervals

- Applications and jobsite selection for HB20G

- Procurement checklist: essential questions before you buy an excavator hydraulic breaker

- Cost of ownership and return on investment

- Brand advantages and what Huilian HB20G brings to Furukawa carriers

- FAQ - Frequently Asked Questions about HB20G and excavator hydraulic breaker procurement

- Is the HB20G compatible with all Furukawa 18-21t models?

- What hydraulic modifications are needed to install the HB20G?

- How often should I replace the tool steel and bushings?

- Can the breaker be used for controlled demolition in urban areas?

- What warranty and after-sales support should I expect?

- Contact sales or view product

- Authoritative references and further reading

Procurement Guide: HB20G Excavator Hydraulic Breaker Furukawa 18-21T

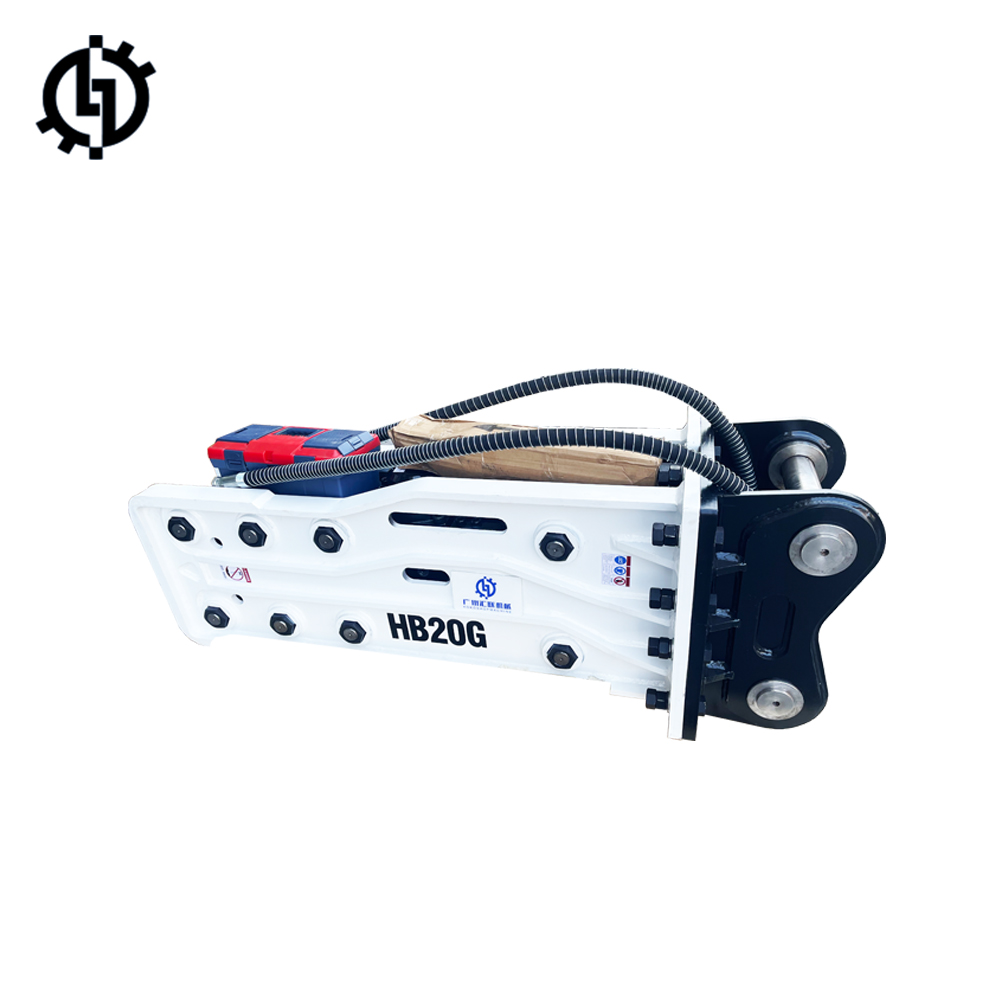

Product Overview: Excavator Hydraulic Rock Breaker Hammer HB20G For Furukawa 18-21 Tons Breaker

The Excavator Hydraulic Rock Breaker Hammer HB20G For Furukawa 18-21 Tons Breaker by Huilian is engineered to meet the needs of medium-weight excavator operators who demand reliable demolition and quarry performance. As an excavator hydraulic breaker, the HB20G delivers consistent impact energy, robust service life, and parts compatibility tailored to Furukawa 18-21 ton base machines. This guide explains key features, technical considerations, procurement criteria, and lifecycle costs to help procurement managers, fleet owners, and site supervisors make an informed purchase decision.

Why choose an excavator hydraulic breaker for Furukawa 18-21t machines

Matching an excavator hydraulic breaker to a Furukawa 18-21 ton machine ensures optimal energy transfer, carrier stability, and tool performance. Excavator hydraulic breaker selection affects productivity, fuel consumption, and wear-part costs. The HB20G is designed to integrate with the hydraulic flow and pressure profiles common to Furukawa 18-21t excavators, offering a balance of blow energy and blow frequency suitable for medium demolition, rock breaking, and trenching tasks.

Key specifications and compatibility

Before procurement, verify mechanical mounting, hydraulic flow, operating pressure, and mass distribution. The table below compares typical values for the HB20G against a Furukawa OEM mid-weight breaker and a generic competitor in the same class. Values are representative ranges intended for procurement evaluation; confirm exact data with manufacturer technical sheets prior to purchase.

| Parameter | Huilian HB20G (typical) | Furukawa Mid-weight OEM (typical) | Generic 18-21t Class Breaker (typical) |

|---|---|---|---|

| Recommended Carrier Weight | 18 - 21 tonnes | 18 - 20 tonnes | 16 - 22 tonnes |

| Operating Pressure | 160 - 210 bar | 160 - 220 bar | 150 - 220 bar |

| Hydraulic Flow Requirement | 80 - 140 L/min | 85 - 145 L/min | 70 - 150 L/min |

| Impact Energy | 1500 - 2100 J | 1400 - 2200 J | 1300 - 2100 J |

| Blow Rate | 300 - 800 bpm | 280 - 820 bpm | 250 - 800 bpm |

| Approx. Breaker Weight | 1200 - 1600 kg | 1100 - 1700 kg | 1000 - 1700 kg |

| Tool Diameter | 70 - 140 mm (varies by chisel) | 75 - 140 mm | 65 - 140 mm |

Performance metrics explained for procurement decisions

Understanding key performance metrics helps match the excavator hydraulic breaker to your tasks. Impact energy indicates the force delivered per blow and correlates to breaking ability on hard rock. Blow rate (bpm) influences how many impacts occur per minute; higher bpm with lower energy suits fracturing and concrete demolition, while lower bpm with higher energy is better for hard rock. Effective productivity is a function of impact energy multiplied by practicable bpm for the material type.

Other important metrics include carrier hydraulic compatibility - the breaker must operate within the carrier's maximum pressure and flow to avoid loss of performance or hydraulic damage. Heat generation and hydraulic oil cleanliness requirements also affect long-term reliability.

Mounting, hydraulics and installation considerations

Proper mounting and hydraulic integration are critical to realizing the performance of an excavator hydraulic breaker. Key steps:

- Confirm bracket dimensions and pin centers match Furukawa boom adapter or provide an adapter kit. Improper mounting increases vibration and reduces productivity.

- Install a dedicated hydraulic circuit with correct relief and flow controls. Use accumulator or anti-blank firing devices if recommended by the breaker manufacturer.

- Fit a flow control valve or a chisel retainer per manufacturer guidance. Ensure hydraulic hoses are rated for the breaker pressure and routed to minimize abrasion and heat exposure.

- Consider mounting dampers or vibration isolators to protect the carrier cab and electronic components.

Maintenance, wear parts and service intervals

Routine maintenance keeps the excavator hydraulic breaker productive and reduces downtime costs. Crucial maintenance items include daily greasing of the tool and bushings, checking nitrogen pre-charge where applicable, monitoring hydraulic oil cleanliness, and inspecting hoses and fasteners. Replace the tool steel and bushings according to wear limits; using hardened tool steel from OEM or certified suppliers extends tool life on abrasive rock.

Recommended maintenance schedule (example):

- Daily: visual inspection, lubrication of tool and piston guide, check hydraulic fittings.

- Weekly: check retaining bolts, condition of hoses, and chisel alignment.

- Every 250 operation hours: inspect piston and bushings, check accumulator pressure if equipped.

- Every 1000 operation hours: comprehensive service including seal replacement and flow testing.

Applications and jobsite selection for HB20G

The HB20G suits a wide range of medium-duty tasks where Furukawa 18-21t excavators operate. Typical applications:

- Quarry secondary breaking and boulder reduction

- Concrete demolition for foundations, retaining walls, and road work

- Trenching in hard ground with embedded rock

- Site clearance where controlled fragmentation reduces explosives use

For each application, match breaker energy and tool type. Use moil points for general breaking, chisels for concrete and cutting, and blunt tools for recycled concrete where rebars are present.

Procurement checklist: essential questions before you buy an excavator hydraulic breaker

Use the following checklist to avoid common procurement pitfalls and to ensure the HB20G or equivalent breaker meets operational needs.

- Is the breaker officially rated for your Furukawa 18-21t excavator hydraulic flow and pressure?

- Does the supplier provide mounting adapters or detailed mounting drawings?

- Are spare parts such as tools, bushings, and seals readily available locally?

- What warranty and service response times does the manufacturer or dealer provide?

- Are recommended hydraulic oil grades and maintenance intervals documented?

- Does the breaker include protective features such as anti-blank firing, accumulator, and integrated shock absorption?

- Can the supplier provide case studies or references for similar applications?

Cost of ownership and return on investment

Initial purchase price is only part of total cost of ownership. Consider fuel savings from faster cycle times, reduced downtime from reliable components, and the cost of wear parts. The simplified table below shows an illustrative cost breakdown comparing two procurement scenarios. Numbers are hypothetical and intended for planning; obtain real quotes for budgeting.

| Cost Item | Huilian HB20G (example) | Generic Competing Breaker (example) |

|---|---|---|

| Initial Purchase | 40,000 USD | 32,000 USD |

| Annual Wear Parts & Service | 6,000 USD | 8,500 USD |

| Average Productivity (m3/day) | 20 | 16 |

| Estimated 3-Year Total Cost | 58,000 USD (with higher productivity) | 57,500 USD (lower productivity) |

While a generic breaker may have a lower purchase price, improved uptime, parts longevity, and higher productivity from a well-matched breaker like the HB20G can deliver better lifecycle value. Calculate ROI by factoring daily production increase, reduced downtime, and parts replacement cadence.

Brand advantages and what Huilian HB20G brings to Furukawa carriers

Huilian positions the HB20G as a companion to Furukawa 18-21t carriers with emphasis on these advantages:

- Carrier-matched hydraulic tuning to protect both excavator and breaker systems

- Robust tool steel and serviceable parts designed for quarry and demolition environments

- Local dealer support networks and easily sourced wear parts to reduce downtime

- Engineered mounting solutions for stable operation and reduced carrier vibration

For procurement teams, these brand advantages translate into predictable performance and lower indirect costs over an equipment lifecycle. Always verify warranty terms and local service capabilities before committing.

FAQ - Frequently Asked Questions about HB20G and excavator hydraulic breaker procurement

Is the HB20G compatible with all Furukawa 18-21t models?

Compatibility depends on hydraulic flow and pressure specifications and the mechanical mounting on the excavator boom. HB20G is designed for the 18-21t class, but confirm exact carrier specifications and request mounting drawings or an adapter kit from the supplier.

What hydraulic modifications are needed to install the HB20G?

Typically a dedicated hydraulic circuit with correct relief settings, a suitable flow control valve, and properly rated hoses are needed. Some installations require accumulators or anti-blank firing systems. Always follow Huilian installation instructions and consult your Furukawa dealer if unsure.

How often should I replace the tool steel and bushings?

Replacement intervals vary by application severity. For heavy quarry use, expect shorter tool life and more frequent bushing replacement. Inspect tool and bushings at regular intervals and schedule replacements before wear reaches critical limits to avoid piston damage.

Can the breaker be used for controlled demolition in urban areas?

Yes. Breakers like the HB20G provide precise, localized breaking and can reduce the need for explosives. Use appropriate noise and vibration mitigation measures, and follow local regulations and safety practices.

What warranty and after-sales support should I expect?

Standard warranties cover manufacturing defects for a specified period or hours of operation. Confirm the exact warranty terms, included service support, and availability of spare parts with the distributor or manufacturer before purchase.

Contact sales or view product

If you are ready to evaluate the Huilian HB20G Excavator Hydraulic Rock Breaker Hammer for your Furukawa 18-21 ton machines, contact your Huilian dealer or request a quotation from our sales team. For hands-on evaluation, ask about demo units, mounting kits, and case studies from similar jobsites. Contact sales to arrange a site compatibility check or to view detailed technical documentation.

Authoritative references and further reading

- https://en.wikipedia.org/wiki/Hydraulic_breaker

- https://en.wikipedia.org/wiki/Excavator

- https://www.hse.gov.uk/construction/index.htm

- https://www.epiroc.com/en/industries/products/hydraulic-breakers

- https://www.furukawakk.co.jp/english/

These resources provide background on hydraulic breakers, excavators, safety guidance, and manufacturer product families. For exact HB20G technical sheets and mounting drawings consult the Huilian product manual or your local Huilian authorized dealer.

Cost-Saving Tips When Buying Wholesale SOOSAN Breaker Parts

Wholesale Excavator Breaker Parts: Complete Buying Guide 2025

Cost Breakdown: Excavator Breaker Parts and Repair Estimates

Everything You Need to Know About Hydraulic Hammer cost

About

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

Huilian OEM Hydraulic Hammer Breaker SB70 For Soosan

Huilian OEM Hydraulic Rock Breaker HB40G For FURUKAWA

C71429 SU+165 TR-F SU+165TRF SU165 SU+165 Seal Kit SU+155 Oil Repair Kit For Excavator Attachment SOOSAN Hydraulic Rock Breaker Hammer Spare Part

Huilian OEM Excavator Hydraulic Cylinder Seal Kit 199-7416 For Caterpillar

Introducing the Huilian OEM Excavator Hydraulic Cylinder Seal Kit 199-7416, designed specifically for Caterpillar machinery. Ensure optimal performance and longevity with our premium Cylinder Seal Kit, crafted for durability and precision. Trust Huilian for reliable, top-quality solutions in hydraulic maintenance. Enhance your equipment's efficiency today!

© 2025 HUILIAN MACHINE. All rights reserved