How much does an excavator hammer weigh? | Huilian Guide

How Much Does an Excavator Hammer Weigh?

Excavator hammers—also known as hydraulic breakers—are vital tools in construction and demolition. Understanding excavator hammer weight is crucial when choosing the right part for your machinery, job site requirements, and workflow efficiency. This article explains common excavator hammer weights, factors influencing them, and best practices for selection.

What Are Excavator Hammers?

- Excavator hammers are hydraulic attachments used for breaking up rock, concrete, and other hard materials.

- Common in construction, mining, and demolition sectors.

- Available in various sizes, models, and output forces.

Average Excavator Hammer Weights

Small Hammers (Mini Excavators: 1-6 tons)

- Typical weight: 60–500 kg (130–1,100 lbs)

- Uses: Light demolition, landscaping, utility jobs.

Medium Hammers (Excavators: 6–20 tons)

- Typical weight: 500–1,500 kg (1,100–3,300 lbs)

- Uses: Infrastructure work, road construction, general demolition.

Large Hammers (Excavators: 20+ tons)

- Typical weight: 1,500–7,000 kg (3,300–15,400 lbs) or more

- Uses: Quarrying, mining, heavy demolition.

_Source: (https://www.komatsueurope.com/), (https://www.cat.com/en_US/products/new/attachments/hammers.html)_

What Determines Excavator Hammer Weight?

- Carrier Size: Larger excavators support heavier hammers.

- Hammer Design: Variations in casing, structure, and built-in dampening affect weight.

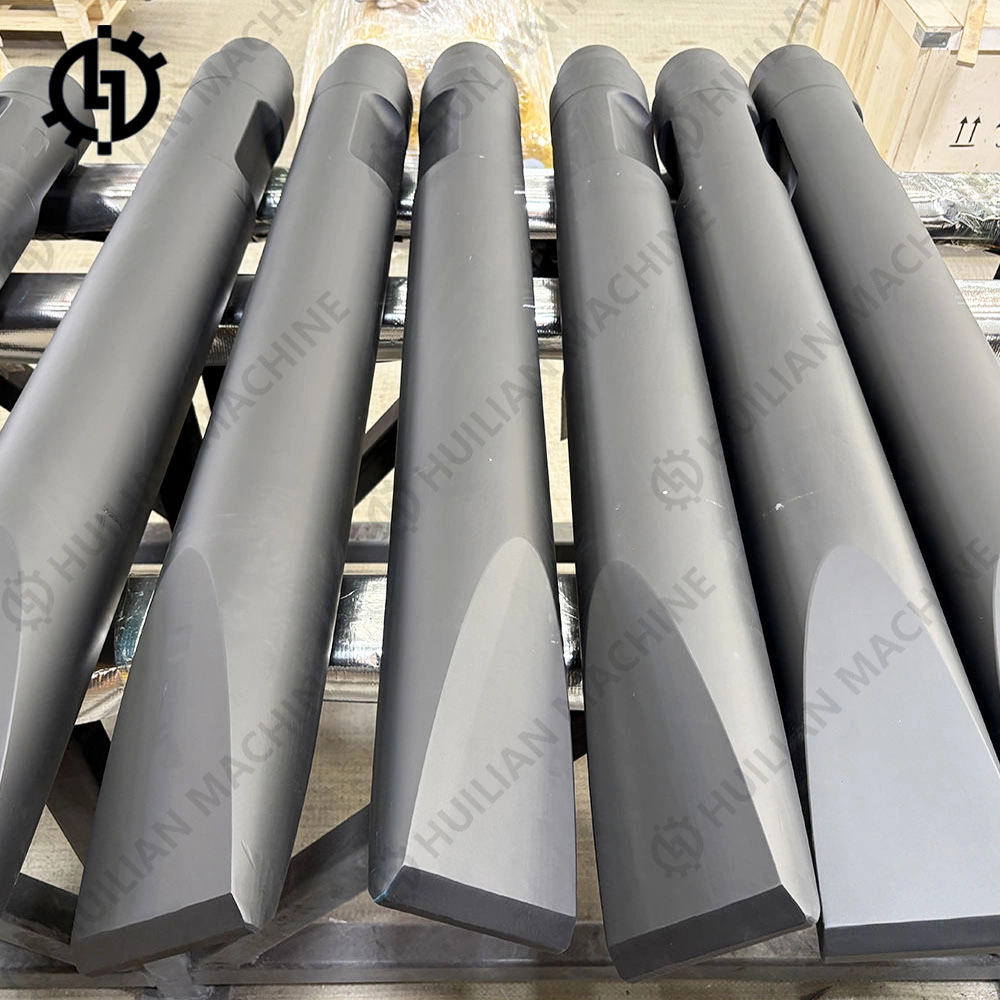

- Tool Specifications: Chisels and moil points contribute to overall weight.

- Operating Conditions: Special models for underwater or high-durability uses may weigh more.

Why Excavator Hammer Weight Matters

- Carrier Matching: Improper weight pairing can damage both hammer and excavator.

- Performance: Heavier hammers deliver higher impact energy, suitable for tougher materials.

- Transport: Heavier hammers increase transportation complexity and costs.

- Safety: Correct weight prevents instability and risk onsite.

Industry Best Practices

- Always consult OEM documentation or suppliers such as Huilian for precise weight specifications.

- Match hammer size to excavator class for best efficiency and safety.

- Conduct regular checks and maintenance for optimal hammer performance.

Quick Reference Conversion

- 1 kilogram ≈ 2.20462 pounds

- Example: 2,000 kg = 4,409 lbs

Key Takeaways

- Excavator hammers range from 60 kg to over 7,000 kg depending on application.

- Weight selection affects job safety, efficiency, and machine compatibility.

- Reference OEM datasheets and industry experienced suppliers like Huilian for guidance.

Looking to source the right excavator hammer or parts? Contact Huilian for expert consultation and reliable supply.

About

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

Getting started is easy

Contact with our experts to find the best excavator parts solutions for your needs. Discover how Huilian can enhance your equipment's performance and efficiency.

Get in touch

© 2025 HUILIAN MACHINE. All rights reserved