Mastering Your Machine: A Comprehensive Guide to Essential Hydraulic Breaker Parts

This comprehensive guide explores the anatomy of hydraulic breakers, detailing essential components like pistons, chisels, seal kits, and bushings. It emphasizes the critical importance of selecting high-quality, OEM-standard parts to ensure equipment durability, safety, and efficiency. Readers will gain insights into compatibility for major brands, the benefits of routine maintenance, and how to source the right spare parts. Whether you need repair kits or specific components, this article provides the knowledge to keep your demolition equipment running at peak performance.

- Introduction: The Heartbeat of Demolition – Understanding Hydraulic Breaker Parts

- Essential Components of a Hydraulic Breaker: A Detailed Breakdown

- Piston: The Engine of Impact

- Chisels & Working Tools

- Seal Kits & Diaphragms

- Bushings

- Front Head & Back Head

- Cylinder

- Accumulator

- Tie Rod Assemblies

- Why Quality Matters: The Benefits of Premium Hydraulic Breaker Parts

- Enhanced Durability & Lifespan

- Superior Performance & Efficiency

- Increased Safety

- Adherence to OEM Standards

- Choosing the Right Parts: Compatibility, Sourcing, and Expert Support

- Brand Compatibility

- New vs. Remanufactured

- Supplier Reputation

- Utilizing Chisel Part Selector Guides

- Maintenance & Repair Essentials for Your Hydraulic Breaker

- Routine Inspections

- Utilizing Service & Repair Kits

- Lubrication: The Lifeblood

- When to Replace Parts

- Conclusion: Investing in Longevity and Performance

- Frequently Asked Questions (FAQ)

- 1. What are the most common hydraulic breaker parts that need replacement?

- 2. Why is using high-quality hydraulic breaker parts important?

- 3. Can I use remanufactured parts for my hydraulic breaker?

- 4. How do I know which parts are compatible with my specific breaker model?

- 5. What are the key maintenance tips for extending the life of hydraulic breaker parts?

- 6. What is a seal kit, and when should it be replaced?

- 7. Do different chisel types exist, and how do I choose the right one?

- 8. Where can I find reliable suppliers for hydraulic breaker parts?

Introduction: The Heartbeat of Demolition – Understanding Hydraulic Breaker Parts

In the rugged environments of construction, mining, and demolition, the hydraulic breaker stands as the heartbeat of productivity. It is a tool designed for punishment, engineered to deliver massive kinetic energy into the hardest materials on earth. However, even the most robust machine is only as reliable as its individual components. When a breaker fails, the silence on a job site is deafening—and expensive. Understanding Hydraulic Breaker Parts is not just a matter of mechanical curiosity; it is a business necessity.

Every time a hammer strikes, a complex symphony of physics and hydraulics occurs. From the high-pressure oil flow to the nitrogen gas expansion, every seal, piston, and bushing plays a pivotal role. Neglecting these components or opting for sub-standard replacements can lead to catastrophic failure, safety hazards, and ballooning repair costs.

This guide covers the essentials of Rock Breaker Parts, from the internal impact mechanisms to the external wear parts. We will explore why quality matters, how to distinguish between OEM Hydraulic Breaker Parts and aftermarket alternatives, and the maintenance strategies that ensure your equipment lasts for years, not just months.

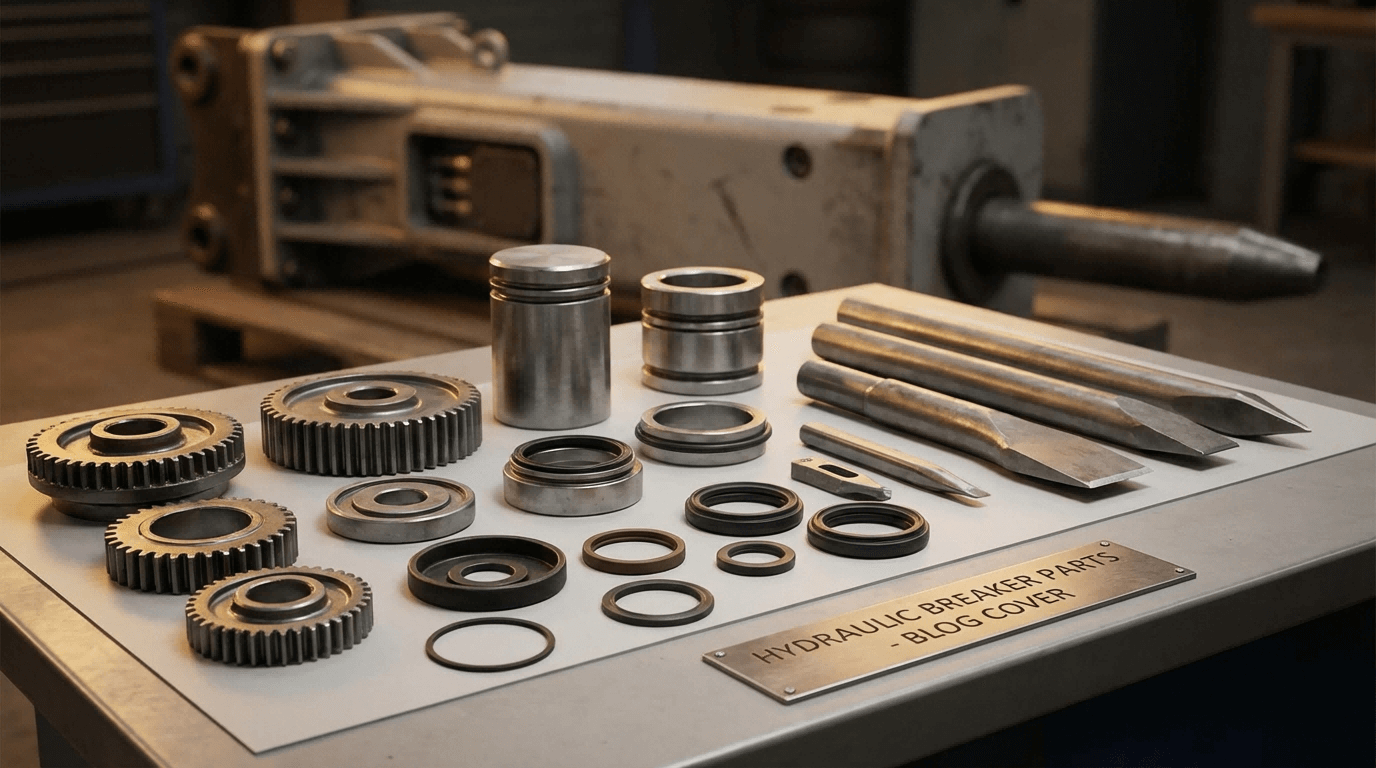

Essential Components of a Hydraulic Breaker: A Detailed Breakdown

To master your machine, you must first understand its anatomy. A hydraulic breaker is a precision instrument disguised as a blunt force tool. Here are the critical components that drive its operation:

Piston: The Engine of Impact

At the core of the breaker lies the Piston for Hydraulic Breaker. This is the primary moving part responsible for generating impact energy. It moves up and down inside the cylinder, accelerated by hydraulic pressure and nitrogen gas. The piston must be manufactured with extreme precision; tolerances are often measured in microns. It strikes the top of the working tool (chisel) to transfer energy into the rock or concrete. Because it is subjected to immense stress, the steel quality and heat treatment of the piston are paramount to prevent cracking or seizing.

Chisels & Working Tools

The Chisel for Hydraulic Breaker (or working tool) is the component that physically contacts the material. It acts as the spear tip, and its shape dictates its efficiency. Choosing the right tool is vital:

· Moil Point: Ideal for general demolition and soft rock, offering a penetrating point.

· Chisel (Wedge): Best for trenching and cutting concrete, as the wedge shape helps split material.

· Blunt Tool: Used for breaking large boulders (secondary breaking) by transferring shock waves rather than penetrating.

· Conical Point: A universal tool for concrete and hard ground.

Seal Kits & Diaphragms

Often overlooked until a leak appears, Breaker Seal Kits are the guardians of pressure. They prevent hydraulic oil from leaking and keep contaminants out. A standard kit includes rod seals, buffer seals, and dust wipers.

Similarly, Diaphragms are used in the accumulator to separate the nitrogen gas from the hydraulic oil. If a diaphragm fails, the gas mixes with the oil, leading to a loss of impact power and potential damage to the hydraulic pump. High-quality seals must withstand high temperatures and pressure spikes.

Bushings

Bushings act as the guidance system for the chisel.

· Lower Bushing: Absorbs the side-thrust and friction from the chisel. It is a high-wear part and usually the first to need replacement.

· Upper Bushing: Guides the upper part of the tool and protects the piston.

· Thrust Ring/Front Cover: Keeps the bushings in place.

Front Head & Back Head

The Front Head (or chuck housing) supports the working tool and bushings, enduring the brute force of the recoil. The Back Head encloses the nitrogen gas chamber and often houses the control valve mechanism. These heavy steel castings provide structural integrity.

Cylinder

The cylinder is the housing in which the piston travels. It contains the hydraulic ports and channels that direct fluid flow. Scratches or damage to the cylinder bore can render the entire breaker useless, necessitating expensive honing or replacement.

Accumulator

The accumulator acts as a shock absorber and energy booster. It stores hydraulic energy during the piston's upward stroke and releases it during the impact stroke to increase power. It also dampens pressure spikes that could otherwise damage the carrier machine's hydraulic pump.

Tie Rod Assemblies

These high-tensile bolts hold the entire sandwich of the breaker (back head, cylinder, front head) together. They are under constant tension. If Tie Rods are not torqued correctly or if they stretch over time, the structural integrity of the breaker is compromised, leading to leaks and misalignment.

Why Quality Matters: The Benefits of Premium Hydraulic Breaker Parts

The market is flooded with Breaker Spare Parts, ranging from high-end OEM components to cheap, unbranded knock-offs. While the price difference can be tempting, the cost of ownership tells a different story.

Enhanced Durability & Lifespan

Premium parts are manufactured using advanced metallurgy. For instance, high-quality pistons and chisels are made from alloy steels that undergo specific heat treatment processes (carburizing or nitriding) to create a hard, wear-resistant surface while maintaining a tough, ductile core. This prevents the part from shattering under impact.

Superior Performance & Efficiency

Hydraulic Hammer Parts engineered to OEM specifications ensure the breaker hits with its rated joule output. A poorly machined piston or a leaking seal kit can result in a 20-30% loss of power. This means it takes longer to break the same amount of rock, burning more fuel and increasing operator hours.

Increased Safety

A failed part can be dangerous. A snapped tie rod can cause the breaker to fall apart during operation. A shattered chisel can send steel shrapnel flying. Investing in quality reduces the risk of catastrophic mechanical failure that could endanger the operator or bystanders.

Adherence to OEM Standards

Whether you buy OEM Hydraulic Breaker Parts or high-quality aftermarket equivalents, ensure they meet the original engineering standards. This includes precision CNC machining to ensure proper fitment. A part that is even slightly off-spec can cause internal friction, overheating, and rapid failure of the entire unit.

Choosing the Right Parts: Compatibility, Sourcing, and Expert Support

Navigating the supply chain for Hydraulic Breaker Repair Kits requires diligence.

Brand Compatibility

Hydraulic breakers are not universal. You need parts that are specifically designed for your make and model. Whether you are running an Atlas Copco, Montabert, Rammer, Indeco, NPK, Soosan, Allied, BTI, CAT, or Epiroc breaker, the internal geometry differs. Always verify part numbers against the manufacturer's diagrams.

New vs. Remanufactured

· New OEM/Aftermarket: The safest bet for critical components like pistons and cylinders.

· Remanufactured: A viable option for expensive, heavy components like cylinders or heads. Reputable suppliers can bore and hone worn cylinders back to spec, offering significant savings without sacrificing performance.

Supplier Reputation

Look for a supplier that specializes in hydraulic attachments. They should offer:

· Large Inventory: To minimize your downtime.

· Technical Support: Experts who can help you identify the correct seal kit based on the serial number, not just a guess.

· Next-Day Delivery: Because every hour your machine sits idle costs money.

Utilizing Chisel Part Selector Guides

Don't just buy "a chisel." Use selector guides to match the tool to the job. Using a blunt tool for concrete works, but it causes excessive vibration. Using a sharp moil point on granite might result in the tip blunting immediately. Matching the metallurgy and shape to the application extends the life of the tool.

Maintenance & Repair Essentials for Your Hydraulic Breaker

Hydraulic Breaker Maintenance is proactive, not reactive. Waiting for the breaker to stop working is a failure of management.

Routine Inspections

Inspect the breaker daily. Check for loose tensioning bolts, oil leaks around the tool, and excessive play in the lower bushing. If the chisel moves side-to-side excessively, the bushings are worn and need immediate replacement to save the piston.

Utilizing Service & Repair Kits

Keep essential kits on hand:

· Seal Kits: Replace these annually or at the first sign of a leak.

· Diaphragm Kits: Check nitrogen pressure regularly.

· Plastic Parts/Wear Plates: These buffers reduce vibration and noise; replace them when they thin out.

Lubrication: The Lifeblood

The most critical factor in chisel and bushing life is lubrication. Use high-temperature Chisel Paste (molybdenum disulfide), not standard chassis grease. Standard grease melts and runs out under the intense heat of a breaker. Auto-lube greaser systems are highly recommended to ensure a continuous supply of lubricant during operation.

When to Replace Parts

· Chisels: Replace when the length shortens significantly or the impact face is deformed.

· Piston: If you see scoring or pitting on the piston surface during a seal change, it requires polishing or replacement.

· Tie Rods: If one breaks, replace the whole set. They stretch evenly; if one snaps, the others are fatigued.

Conclusion: Investing in Longevity and Performance

Your hydraulic breaker is a significant investment, capable of generating immense revenue when running efficiently. The parts you choose—from the Piston for Hydraulic Breaker to the humble seal kit—dictate the machine's profitability.

By prioritizing high-quality components, adhering to strict maintenance schedules, and partnering with reputable suppliers who understand the intricacies of brands like Montabert and Rammer, you ensure operational efficiency. Remember, in demolition, the cheapest part is often the one that lasts the longest. Invest in quality, maintain your machine, and it will serve as the reliable heartbeat of your operation for years to come.

Frequently Asked Questions (FAQ)

1. What are the most common hydraulic breaker parts that need replacement?

The most commonly replaced parts include chisels/working tools, seal kits, bushings (upper and lower), diaphragms, and sometimes pistons, due to constant wear and high impact stress.

2. Why is using high-quality hydraulic breaker parts important?

High-quality parts ensure optimal performance, extend the lifespan of the breaker, enhance safety, reduce costly downtime, and maintain the efficiency of demolition tasks.

3. Can I use remanufactured parts for my hydraulic breaker?

Yes, remanufactured parts can be a cost-effective alternative, provided they are sourced from reputable suppliers who adhere to strict quality control and OEM standards to ensure reliability and performance.

4. How do I know which parts are compatible with my specific breaker model?

Always refer to your breaker's operator manual or consult with a specialized supplier, providing them with your breaker's make, model, and serial number for accurate compatibility matching.

5. What are the key maintenance tips for extending the life of hydraulic breaker parts?

Regular lubrication with chisel paste, daily inspections for wear and leaks, ensuring proper hydraulic fluid levels, and replacing worn seal kits promptly are crucial for longevity.

6. What is a seal kit, and when should it be replaced?

A seal kit contains various seals and O-rings essential for maintaining hydraulic pressure and preventing leaks. It should be replaced during routine service or immediately if any leaks are detected or performance drops.

7. Do different chisel types exist, and how do I choose the right one?

Yes, there are various chisel types (e.g., conical point, blunt, wide, moil) designed for specific applications like concrete breaking, asphalt cutting, or rock demolition. Choose based on the material and task at hand, often guided by a chisel selector chart.

8. Where can I find reliable suppliers for hydraulic breaker parts?

Look for suppliers with extensive inventory for multiple brands, a reputation for quality parts (often mentioning OEM standards, specific materials, and manufacturing processes), and strong technical support with fast delivery options.

About

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

Getting started is easy

Contact with our experts to find the best excavator parts solutions for your needs. Discover how Huilian can enhance your equipment's performance and efficiency.

Get in touch

© 2025 HUILIAN MACHINE. All rights reserved