parker diaphragm accumulator cost | Huilian Expert Guide

Understanding Parker Diaphragm Accumulator Costs for Excavator Parts

When it comes to maintaining and optimizing the performance of excavators, hydraulic accumulators play a vital role. Parker diaphragm accumulators are a popular choice due to their reliability and efficiency. However, understanding the factors that influence their cost is crucial for making informed purchasing decisions.

What are the common questions about Parker diaphragm accumulator costs?

Based on common search queries, here are some frequently asked questions regarding Parker diaphragm accumulator costs:

What factors affect the price of a Parker diaphragm accumulator?

- Size and Capacity: Larger accumulators with greater fluid storage capacity generally cost more. The volume of the accumulator directly impacts the materials and manufacturing complexity.

- Material: The material used in the accumulator's construction influences the price. Common materials include carbon steel and stainless steel, with stainless steel options being more expensive due to their corrosion resistance.

- Pressure Rating: Accumulators designed for higher pressure applications require stronger materials and more precise engineering, thus increasing their cost.

- Features and Options: Additional features such as integrated pressure gauges, safety valves, and specific mounting options can also impact the price.

- Vendor and Distribution Channel: Prices may vary depending on the vendor, distributor, or online retailer. It's essential to compare prices from multiple sources to find the best deal.

Where can I buy Parker diaphragm accumulators at the best price?

- Authorized Distributors: Purchasing from authorized Parker distributors ensures you receive genuine products and warranty support. While prices might be slightly higher, the assurance of quality is valuable.

- Online Retailers: Online platforms offer a wide range of Parker accumulators, often at competitive prices. However, it's crucial to verify the seller's credibility and the product's authenticity.

- Direct from Parker: In some cases, purchasing directly from Parker or their official online store might be an option, especially for bulk orders or specialized requirements.

- Surplus and Used Markets: Consider exploring surplus equipment markets or used parts dealers. While this can lead to significant cost savings, carefully inspect the accumulator's condition and ensure it meets your specifications.

How does the cost of a Parker diaphragm accumulator compare to other brands?

- Parker accumulators are generally positioned as a High Quality product, reflecting their quality and reliability. Brands like Bosch Rexroth, Eaton, and Hydac offer competing diaphragm accumulators.

- Cost comparisons should consider specifications like capacity, pressure rating, and material. While some brands may offer lower prices, it's essential to evaluate the long-term value and reliability.

What is the typical lifespan of a Parker diaphragm accumulator, and how does it affect the overall cost?

- The lifespan of a Parker diaphragm accumulator depends on factors such as operating conditions, maintenance practices, and the quality of the hydraulic fluid. Typically, they can last for several years with proper care.

- Regular inspections and maintenance, including checking the pre-charge pressure and inspecting for leaks, can extend the accumulator's lifespan.

- While the initial cost might be higher, a longer lifespan translates to fewer replacements and lower overall operating costs.

Are there any alternatives to Parker diaphragm accumulators, and how do their costs compare?

- Bladder Accumulators: Bladder accumulators are another common type. They generally offer larger capacity but might be more susceptible to wear and tear in certain applications. Their cost can vary but is often comparable to diaphragm accumulators.

- Piston Accumulators: Piston accumulators are suitable for high-pressure and high-volume applications. They tend to be more expensive than diaphragm accumulators but offer greater durability and longer service life.

Real Data and Knowledge Points

Parker diaphragm accumulators are known for their consistent performance and leak-free design. They utilize a flexible diaphragm to separate the gas and fluid, preventing gas permeation and ensuring reliable operation. According to Parker's official documentation, their diaphragm accumulators are designed to maintain pre-charge pressure for extended periods, reducing the need for frequent maintenance.

When comparing prices, always consider the specific model number and specifications. For example, a Parker diaphragm accumulator with a 1-liter capacity and a 210 bar pressure rating might cost between $300 and $600, depending on the vendor and material. Prices can fluctuate based on market conditions and availability.

Disclaimer: The pricing information provided here is for illustrative purposes only and should not be considered as definitive. Always consult with authorized Parker distributors or suppliers for accurate and up-to-date pricing.

About

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

What types of excavator parts do you offer?

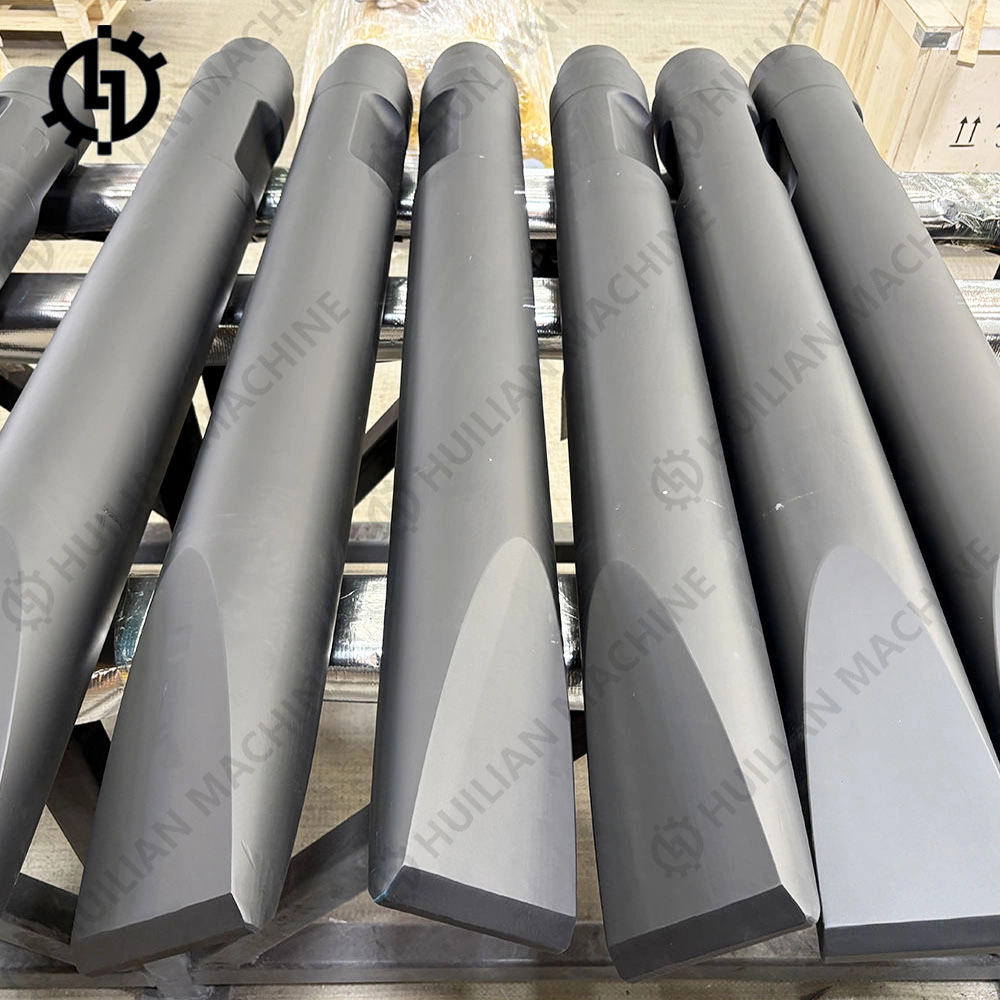

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

Getting started is easy

Contact with our experts to find the best excavator parts solutions for your needs. Discover how Huilian can enhance your equipment's performance and efficiency.

Get in touch

© 2025 HUILIAN MACHINE. All rights reserved