diaphragm accumulator parker cost | Huilian Expert Guide

- Diaphragm Accumulator Costs for Excavator Parts: A Guide for Industry Buyers

- What Factors Influence the Cost of Parker Diaphragm Accumulators?

- How Can Buyers Find Cost-Effective Parker Diaphragm Accumulators?

- Why Choose Parker Diaphragm Accumulators Over Competitors for Excavators?

- What Are the Maintenance Costs Associated with Parker Diaphragm Accumulators?

- How Do Industry Trends in 2025 Impact Diaphragm Accumulator Costs?

Diaphragm Accumulator Costs for Excavator Parts: A Guide for Industry Buyers

In the excavator parts industry, hydraulic components like diaphragm accumulators play a crucial role in maintaining system performance by storing energy, absorbing shocks, and dampening pulsations. Parker, a leading manufacturer, offers reliable and lightweight diaphragm accumulators tailored for heavy machinery like excavators. However, understanding the cost dynamics of these components is vital for procurement professionals aiming to balance quality and budget. This article addresses the top 5 concerns and questions regarding diaphragm accumulator costs, particularly for Parker products, to assist buyers in making informed decisions.

What Factors Influence the Cost of Parker Diaphragm Accumulators?

The cost of Parker diaphragm accumulators, such as the AD and DA series, varies based on several factors. These include the accumulator’s size and gas volume capacity (ranging up to 170 cu. in. or 2.80L as per Parker specifications), pressure rating, and material compatibility with hydraulic fluids. Additional cost drivers include customization for specific excavator models, regional availability, and shipping expenses. While exact pricing isn’t publicly listed on Parker’s official resources, industry trends suggest that compact, lightweight designs like Parker’s can be more cost-effective compared to heavier bladder or piston accumulators, offering savings in installation and maintenance.

How Can Buyers Find Cost-Effective Parker Diaphragm Accumulators?

To secure cost-effective Parker diaphragm accumulators, buyers in the excavator parts industry should focus on authorized distributors like those listed on Parker NA’s website (ph.parker.com). Bulk purchasing often results in discounts, and comparing quotes from multiple suppliers can yield competitive pricing. Additionally, exploring regional suppliers or partners listed on platforms like Hydraulics Online can reduce shipping costs. It’s also beneficial to assess the total cost of ownership, as Parker’s durable designs minimize long-term replacement and downtime expenses.

Why Choose Parker Diaphragm Accumulators Over Competitors for Excavators?

Parker diaphragm accumulators stand out due to their lightweight and compact design, making them ideal for excavators where space and weight are critical, as highlighted on Parker’s product pages. Their ability to store energy under pressure and absorb hydraulic shocks ensures optimal performance in rugged environments. Compared to competitors, Parker’s accumulators are often praised for reliability and ease of installation, potentially reducing labor costs during excavator maintenance. Industry feedback from sources like GS Global Resources emphasizes Parker’s affordability alongside performance.

What Are the Maintenance Costs Associated with Parker Diaphragm Accumulators?

Maintenance costs for Parker diaphragm accumulators are generally lower than for other types due to their simple design. Regular inspection for diaphragm wear, pressure checks, and fluid compatibility assessments are recommended to extend lifespan. While specific costs depend on usage and environment, Parker’s documentation suggests that proper maintenance can prevent costly system failures in excavators. Buyers should budget for periodic replacement of diaphragms, which is less expensive than full unit replacement, ensuring long-term cost efficiency.

How Do Industry Trends in 2025 Impact Diaphragm Accumulator Costs?

As of 2025, the hydraulic accumulator market, including diaphragm types, is influenced by rising demand for fuel-efficient and low-emission heavy machinery, as noted in recent industry reports like those from openPR.com on related markets. This trend drives innovation in compact components like Parker’s accumulators, potentially stabilizing or reducing costs due to increased production. However, supply chain challenges and raw material price fluctuations could impact costs. Buyers should monitor market analyses and forecasts for excavator parts to anticipate price shifts and plan procurement strategies accordingly.

In conclusion, understanding the cost dynamics of Parker diaphragm accumulators is essential for excavator parts buyers. By focusing on key factors like supplier selection, maintenance planning, and industry trends in 2025, procurement professionals can optimize budgets while ensuring high performance. Leveraging Parker’s reputation for quality and affordability, as supported by resources from Parker NA and industry partners, can guide smarter purchasing decisions in this competitive sector.

About

What types of excavator parts do you offer?

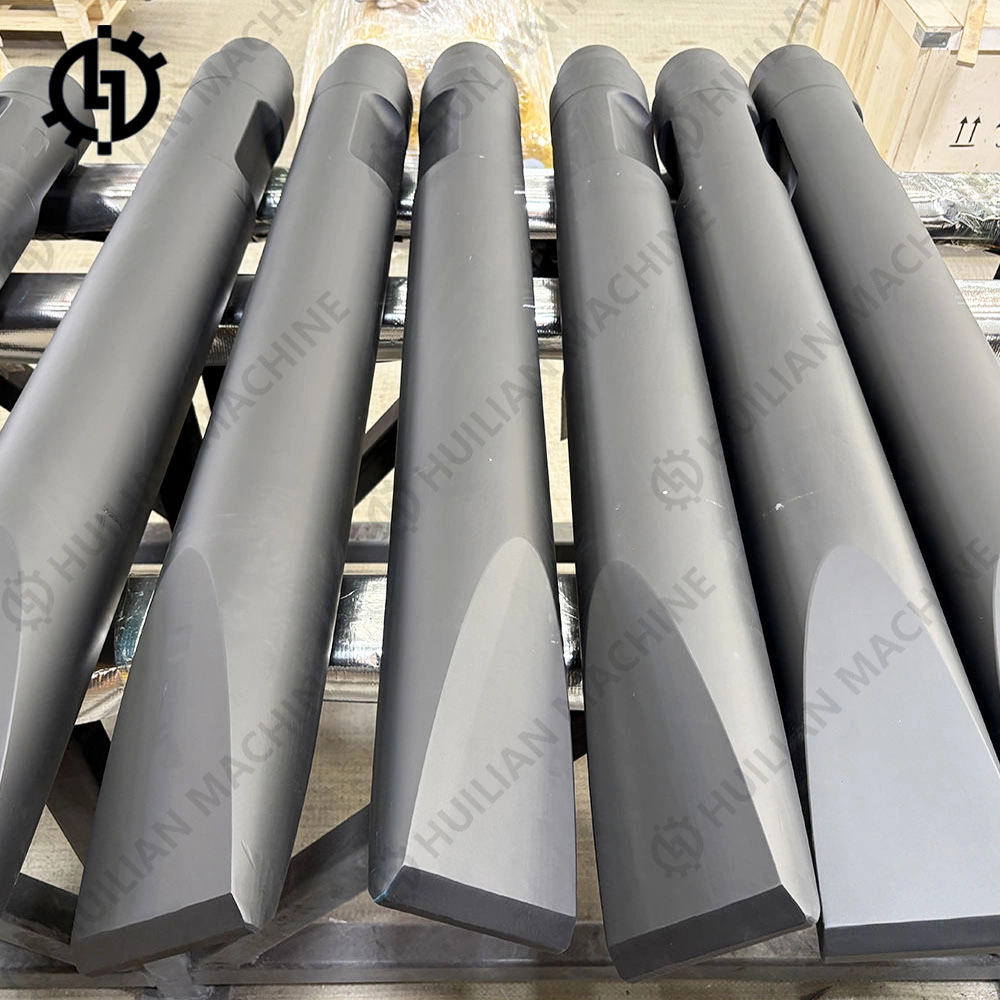

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

Getting started is easy

Contact with our experts to find the best excavator parts solutions for your needs. Discover how Huilian can enhance your equipment's performance and efficiency.

Get in touch

© 2025 HUILIAN MACHINE. All rights reserved