Procurement Checklist: D81115-D81119 Rock Hammer Parts

- Procurement Checklist: D81115-D81119 Rock Hammer Parts

- Product overview — Hydraulic Breaker Chisel for Soosan SB131 / SB130

- Why the right Hydraulic Breaker Chisel matters for procurement

- Compatibility checklist: confirm model and part interchangeability

- Technical specifications to verify for D81115–D81119 Hydraulic Breaker Chisel

- Material and metallurgy: why Cr42 matters for rock hammer parts

- Chisel tip types and application mapping — choose the right D8111x variant

- Quality control and acceptance testing for incoming chisel shipments

- Supplier evaluation: what to require from D8111x hydraulic rock hammer parts vendors

- Warranty and lifecycle expectations for Hydraulic Breaker Chisel parts

- Spare parts strategy and inventory levels for minimizing downtime

- Packaging, transportation and storage requirements

- Installation and pre-service checklist for new chisel parts

- Performance metrics to monitor after procurement

- Cost analysis and total cost of ownership (TCO) considerations

- Brand advantages and why choose Huilian 165mm Soosan chisel parts

- Documentation and traceability requirements to include in purchase orders

- Procurement checklist summary (quick action list)

- FAQ — Frequently Asked Questions about D81115–D81119 Hydraulic Breaker Chisel

- Q: Are D81115–D81119 parts interchangeable across Soosan SB130 and SB131?

- Q: How long do Cr42 rod bits typically last?

- Q: What tests should I require on delivery?

- Q: Can I use these chisels for recycling or concrete demolition?

- Q: What spare parts should I keep onsite in addition to chisels?

- Authoritative references and further reading

Procurement Checklist: D81115-D81119 Rock Hammer Parts

Product overview — Hydraulic Breaker Chisel for Soosan SB131 / SB130

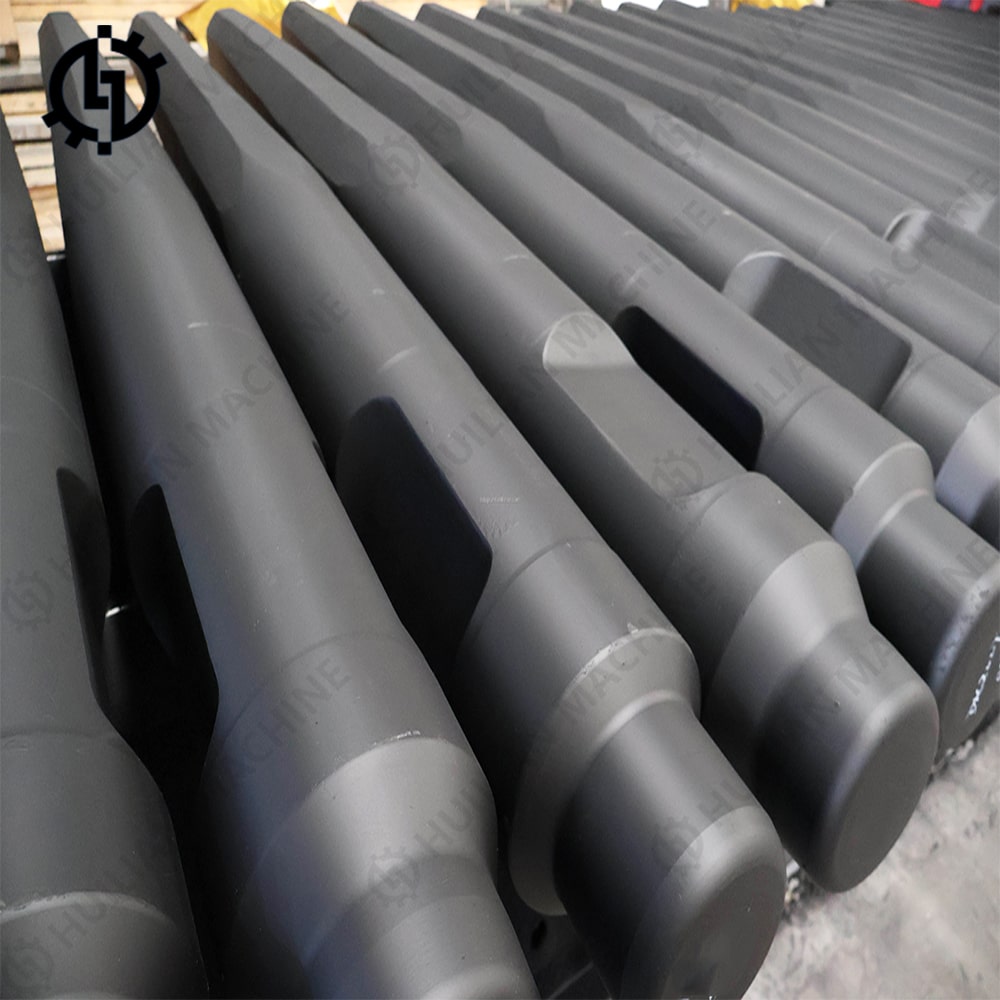

Huilian 165mm Soosan SB131 SB140 SB130 Hydraulic Breaker Chisel features durable D81115 D81118 D81117 D81116 D81119 hydraulic rock hammer parts, including moil point, wedge, blunt cone, and Cr42 rod bits. Ideal for SB131 and SB130 breaker chisels, ensuring high performance and longevity in heavy-duty applications.

Why the right Hydraulic Breaker Chisel matters for procurement

Choosing the correct Hydraulic Breaker Chisel directly affects breaker performance, operating costs, and jobsite uptime. A mismatch in chisel type, size, or material can cause accelerated wear, frequent downtime, and reduced productivity. Procurement professionals must therefore evaluate compatibility, metallurgy, manufacturing tolerances, and supplier reliability before purchasing D81115-D81119 chisel parts for Soosan SB131 / SB130 breakers.

Compatibility checklist: confirm model and part interchangeability

Before placing an order, verify the chisel part numbers and physical dimensions match the breaker make and model. For the Huilian 165mm Soosan series chisel set (D81115 — D81119), confirm the following items:

- Breaker model compatibility (SB131, SB130, SB140 where applicable).

- Chisel diameter and working length (165mm reference in product name).

- Tool retainer and bushing fitment—ensure the tool retention system on the breaker accepts these rod bits.

- Tip geometry matching operating task: moil point for general breaking, wedge for demolition and splitting, blunt cone for compacting and bedrock, and blunt/wear profiles for specific rock types.

Technical specifications to verify for D81115–D81119 Hydraulic Breaker Chisel

Procurement should capture and verify the full technical specification sheet. Key specs include:

- Material grade (Cr42 indicated for rod bits).

- Hardness range (typically specified after heat treatment).

- Surface treatment, e.g., induction hardened tip or through-hardened rod.

- Dimensional tolerances and concentricity tolerances.

- Manufacturing process controls (forged vs. machined, heat-treatment records).

Material and metallurgy: why Cr42 matters for rock hammer parts

Cr42 (a chromium-containing steel grade commonly used for tool steel applications) delivers an effective balance of wear resistance and toughness. For hydraulic breaker chisels the critical areas are the tip and the transitional shoulder. Procurement should confirm:

- Chemical composition certificate (material certification / mill test report).

- Hardness testing records (Rockwell or equivalent) especially at the tip and shank.

- Evidence of controlled heat treatment to avoid brittleness or excessive soft zones.

Chisel tip types and application mapping — choose the right D8111x variant

Selecting the correct tip geometry extends service life and boosts productivity. Below is a typical mapping of D81115–D81119 parts to tip styles and primary applications:

| Part Number | Tip Style | Primary Applications | Notes |

|---|---|---|---|

| D81115 | Moil Point | General breaking, trenches, asphalt | Good all-round performer |

| D81116 | Wedge | Demolition, splitting layered rock | Better for prying and splitting |

| D81117 | Blunt Cone | Compacting, breaking hard bedrock | Designed for concentrated impact |

| D81118 | Blunt/Long-life | Abrasive conditions, recycling | Enhanced wear profile |

| D81119 | Cr42 Rod Bit (general) | Replacement rod bits for SB130/SB131 | High toughness shank |

Quality control and acceptance testing for incoming chisel shipments

Never accept a shipment without a documented inspection. Standard acceptance tests procurement should require:

- Visual inspection for cracks, surface imperfections, or machining damage.

- Dimensional verification with calipers/coordinate measurement for critical diameters and lengths.

- Hardness spot checks (at tip & shank) and a sample full hardness curve if available.

- Material traceability: mill test reports (MTR) linked to batch numbers.

- Sample metallographic or chemical analysis for disputed batches.

Supplier evaluation: what to require from D8111x hydraulic rock hammer parts vendors

Choosing the right supplier reduces procurement risk. Key criteria include:

- Production capacity and lead times—confirm they can meet peak demands without quality trade-offs.

- Quality management system certification (e.g., ISO 9001).

- Field test references and case studies for SB130/SB131 applications.

- After-sales support: replacement policies, warranty, and technical assistance.

- Ability to provide full inspection documentation and traceability for each batch.

Warranty and lifecycle expectations for Hydraulic Breaker Chisel parts

Understand what warranty covers: defects in material and workmanship vs. wear from normal use. Typical supplier warranties exclude normal wear but protect against premature failure due to defective heat treatment or material. Expect operational life to vary widely—examples:

- Soft rock / intermittent use: higher tip life (months).

- Abrasive rock / continuous heavy duty: tip life shorter (weeks to months).

Always request benchmark data from the supplier (hours-per-life or cubic meters broken per chisel) for your type of work as part of the procurement negotiation.

Spare parts strategy and inventory levels for minimizing downtime

Create a spare parts plan based on utilization and lead time. A typical recommendation for high-utilization fleets using 165mm chisels:

- Critical fleet (24/7 operations): keep 3–5 spare chisels per breaker unit (mix of moil and blunt types).

- Medium utilization: 1–2 spares per breaker.

- Low utilization: 1 spare set per several breakers.

Maintain a log of hours on each chisel to predict replacement intervals and avoid reactive procurement. Include retaining pins, bushings, and seals in the spare kit to perform a full onsite changeover.

Packaging, transportation and storage requirements

Ensure proper packaging and storage practices to avoid rust and mechanical damage during transit and storage. Procurement should specify:

- Rust-inhibitor / oil film and sealed cartons for overseas shipping.

- Individual part marking with part number and batch code.

- Indoor, dry storage with protective end-caps to prevent tip damage.

Installation and pre-service checklist for new chisel parts

Upon installation, follow these steps to ensure immediate reliable performance:

- Inspect matching surfaces and tool retainer before assembly.

- Verify retaining pin condition and replace if worn.

- Torque and fit checks as per breaker OEM guidance.

- Run-in procedure: start in low-impact mode for first 10–20 minutes to seat components and verify fit.

Performance metrics to monitor after procurement

Track these KPIs to evaluate supplier value and optimize procurement cycles:

- Hours per chisel/part until replacement.

- Cost per operating hour including downtime.

- Frequency of unexpected failures or warranty claims.

- Rate of return for remanufacture or recycling.

Cost analysis and total cost of ownership (TCO) considerations

Price-per-piece is only one part of procurement decisions. Include these items in TCO calculations:

- Part unit price and freight.

- Expected life (hours) and replacement frequency.

- Labor cost for changeover and associated downtime cost.

- Warranty and replacement policy that reduce unexpected costs.

Brand advantages and why choose Huilian 165mm Soosan chisel parts

When evaluating vendors, Huilian's offering of 165mm Soosan SB131 SB140 SB130 Hydraulic Breaker Chisel D81115–D81119 has several advantages aligned with procurement priorities:

- Purpose-built compatibility with Soosan SB130/SB131 models, reducing fitment risk.

- Use of Cr42 rod bits for a balance of toughness and wear resistance.

- Range of tip geometries (moil, wedge, blunt) to match site-specific applications.

- Comprehensive documentation potential—material certificates and hardness testing available on request.

- After-sales support and the ability to supply spare kits for faster changeovers.

Documentation and traceability requirements to include in purchase orders

Require the following with your PO to protect operations and ensure compliance:

- Part number and revision (D81115–D81119) and exact quantity with batch numbers.

- Material certificate (MTR) and hardness results.

- Inspection report and Conformity of Origin (if required).

- Warranty terms and expected lead times for future supply.

Procurement checklist summary (quick action list)

- Confirm model compatibility and tip geometry.

- Require Cr42 material certs and hardness reports.

- Inspect dimensions and hardness on arrival.

- Maintain spare strategy based on utilization.

- Evaluate supplier for ISO quality management and field references.

- Negotiate warranty and required documentation in the PO.

FAQ — Frequently Asked Questions about D81115–D81119 Hydraulic Breaker Chisel

Q: Are D81115–D81119 parts interchangeable across Soosan SB130 and SB131?

A: Many of the D8111x parts are designed to fit SB130 and SB131, but always confirm diameters, retention system fit and length. Confirm interchangeability with a supplier drawing or fitment checklist before ordering in bulk.

Q: How long do Cr42 rod bits typically last?

A: Life varies by application. Typical ranges are from a few hundred hours in very abrasive, continuous use to several thousand hours in light-duty operations. Request supplier field data for similar applications to estimate lifetime for your site.

Q: What tests should I require on delivery?

A: Visual inspection, dimensional check, spot hardness tests, and MTR/mill certificates for material composition. For suspicious batches, consider send-out hardness curves or chemical analysis.

Q: Can I use these chisels for recycling or concrete demolition?

A: Yes—choose the correct tip style. Wedge or blunt long-life tips are preferred for concrete and recycling applications due to higher abrasion and impact demands.

Q: What spare parts should I keep onsite in addition to chisels?

A: Retaining pins, bushings, and upper/lower seals for the breaker. Keeping a full changeover kit reduces downtime significantly.

Authoritative references and further reading

- Hydraulic breaker — Wikipedia

- International Organization for Standardization (ISO) — ISO.org

- MatWeb Material Property Data — matweb.com

- Engineering Toolbox — engineeringtoolbox.com

For any procurement assistance, specification templates, or to schedule a technical review of your breaker fleet and spare strategy, contact our specialists using the email above.

Cost vs Quality: Buying Rock Breaker Seal Kits for Contractors

Wholesale Rammer hydraulic breaker manufacturer and supplier in China

How to Choose Hydraulic Seal Kits for Excavator Booms

Wholesale Parker excavator seal kits manufacturer and supplier

About

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

Huilian OEM Hydraulic Rock Breaker HB40G For FURUKAWA

C71429 SU+165 TR-F SU+165TRF SU165 SU+165 Seal Kit SU+155 Oil Repair Kit For Excavator Attachment SOOSAN Hydraulic Rock Breaker Hammer Spare Part

Huilian OEM Excavator Hydraulic Cylinder Seal Kit 199-7416 For Caterpillar

Introducing the Huilian OEM Excavator Hydraulic Cylinder Seal Kit 199-7416, designed specifically for Caterpillar machinery. Ensure optimal performance and longevity with our premium Cylinder Seal Kit, crafted for durability and precision. Trust Huilian for reliable, top-quality solutions in hydraulic maintenance. Enhance your equipment's efficiency today!

OEM Excavator Spare parts PC2000-8 Track Adjuster Seal Kit For Komatsu

Huilian OEM Excavator Spare Parts PC2000-8 Track Adjuster Seal Kit for Komatsu. Ensures optimal track adjustment performance. High-quality replacement for your PC2000-8 excavator. Order your kit today!

© 2025 HUILIAN MACHINE. All rights reserved