Top 10 Reasons Why Hydraulic Breaker Bits Are Essential for Heavy Equipment Efficiency

This is an introduction to hydraulic breaker bits.

In today's fast-paced construction and mining industries, hydraulic breaker bits are important for being more efficient, having better performance, and being safer. These small but powerful tools are the heart of hydraulic breakers. They enable operators to crush, demolish, and excavate even the toughest materials. The right breaker bit is important for road construction, quarrying, and demolition. It can make a big difference in how much work you can get done and how much it costs.

What Are Hydraulic Breaker Bits?

A hydraulic breaker bit is a tool that can be replaced. It is the part of a hydraulic breaker that is attached at the end. It's built to handle extreme impacts and pressures as it moves energy from the hydraulic system directly to rock or concrete surfaces.

These bits are made from a strong type of steel. They are made stronger by heating them during the manufacturing process. This makes them last a long time.

How hydraulic breaker bits work

The breaker bit works using hydraulic energy conversion. When pressurized oil from an excavator's hydraulic system enters the breaker, it drives a piston that repeatedly strikes the bit. The bit delivers concentrated impact energy to the material, breaking it into smaller, manageable pieces.

This efficient energy transfer system makes sure that the machine is productive and does not wear out.

Types of Hydraulic Breaker Bits:

Choosing the right breaker bit depends on the material you’re working with and the desired result. Let’s explore the most common types:

Moil Point Bit:

Designed for general-purpose breaking, the moil point bit has a sharp, pointed end that delivers concentrated impact energy—ideal for breaking hard rock or reinforced concrete.

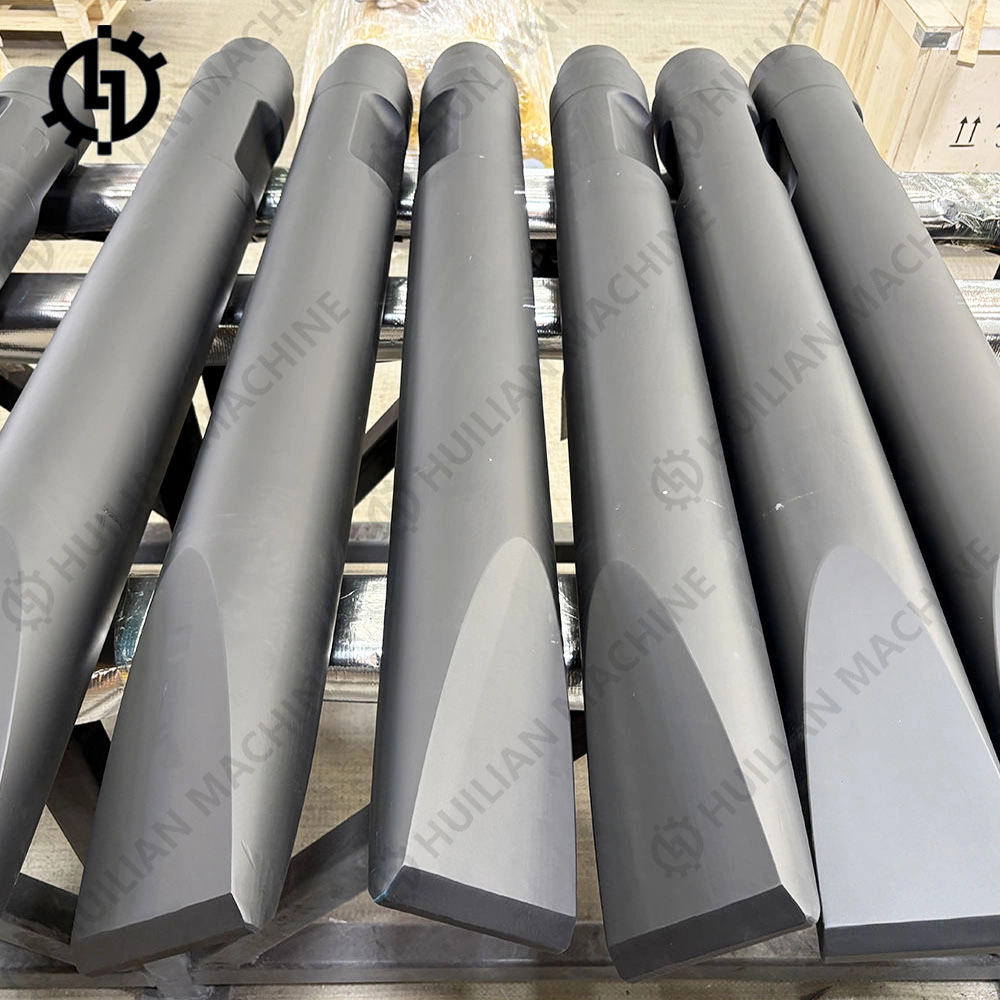

Chisel Bit:

Chisel bits have a flat, narrow tip, suitable for cutting through asphalt or concrete slabs. Their precision and control make them perfect for trenching and foundation work.

Blunt Bit:

A blunt bit has a flat surface that distributes impact evenly, making it effective for breaking large, brittle materials, like rocks or frozen ground.

Cone Bit:

Cone bits feature a conical tip, used mainly in quarrying and mining operations where deep penetration and high-impact energy are required.

Pyramid Bit:

The pyramid bit provides multiple contact points, delivering powerful blows for specialized demolition tasks that require precision.

Materials and Manufacturing Process:

High-quality hydraulic breaker bits are made from premium-grade alloy steel and are engineered to withstand heavy impacts. The manufacturing process involves:

- Forging for high density and strength

- Heat treatment to achieve optimal hardness

- Precision machining for a perfect fit and optimal performance.

Heat treatment and hardness

Proper heat treatment enhances toughness and prevents premature wear or cracking. Each Guangzhou Huilian Machine breaker bit undergoes strict quality control to ensure durability under extreme conditions.

OEM vs Aftermarket Hydraulic Breaker Bits

When purchasing breaker bits, customers often choose between OEM (Original Equipment Manufacturer) and aftermarket parts.

OEM bits are designed by the same manufacturer that produced your breaker, ensuring perfect compatibility and reliability.

Aftermarket bits, when sourced from trusted suppliers like Guangzhou Huilian Machine, can provide equal or superior quality at a more affordable price.

Applications of Hydraulic Breaker Bits

Excavation and Road Construction

Breaker bits are essential for digging foundations, removing concrete, roads, and shaping hard surfaces.

Mining and Quarrying

In the mining industry, these bits are used to break large rocks, extract ore, and reduce material size efficiently.

Demolition and Recycling

Hydraulic breaker bits make demolition faster and safer, helping operators dismantle structures and prepare materials for recycling.

Maintenance Tips for Hydraulic Breaker Bits

Proper maintenance not only extends the life of your breaker bits, but also improves equipment efficiency.

Cleaning and Lubrication

Regular cleaning prevents dust and debris buildup, while lubrication reduces friction and heat generation.

Inspection and Replacement

Inspect bits regularly for cracks or deformation. Replace worn-out bits promptly to avoid damage to the breaker or excavator arm.

Common Problems and Troubleshooting

Excessive Wear: May result from using the wrong bit type.

Overheating: Indicates poor lubrication or continuous operation.

Reduced impact power: Often caused by hydraulic system issues or worn pistons.

Choosing the Right Hydraulic Breaker Bits

When selecting a breaker bit, consider the following factors:

Material hardness

Impact energy and breaker capacity

Bit shape and design

Compatibility with brand models (e.g., Atlas Copco, Montabert, Furukawa, Soosan, JCB, Toku, Krupp, NPK, EDT, Okada etc.)

Guangzhou Huilian Machine — Your Trusted Supplier for Hydraulic Breaker Bits!

Guangzhou Huilian Machine Co., Ltd. has been a leading supplier of hydraulic breaker parts and seal kits for over 16 years in Guangzhou, China.

With a 2000-square-meter factory and multiple production lines, EB Seals offers high-quality OEM and aftermarket replacement parts for nearly all major breaker brands.

Our Strengths:

16 years of manufacturing expertise

Advanced production technology

Strict quality control and premium materials

Global shipping and after-sales support!

Visit our official site for more details: https://www.huilianmachine.com/

FAQs About Hydraulic Breaker Bits

Q1. What are the most common types of hydraulic breaker bits?

A1. Moil, point, chisel, blunt, cone, and pyramid bits are the most widely used types.

Q2. How long do hydraulic breaker bits last?

A2. Depending on usage and material, they can last from several weeks to months with proper maintenance.

Q3. Can I use any breaker bit with my hydraulic hammer?

A3. No, always ensure compatibility based on the breaker’s size, power, and model.

Q4. How can I tell if a breaker bit is worn out?

A4. Visible cracks, reduced impact strength, and deformed tips indicate it’s time for replacement.

Q5. Are aftermarket breaker bits as reliable as OEM?

A5. Yes, when sourced from reputable manufacturers like EB Seals, aftermarket bits perform equally well.

Q6. What industries use hydraulic breaker bits the most?

A6. Construction, mining, roadwork, and demolition industries rely heavily on these tools.

Conclusion: The Future of Hydraulic Breaker Bits

As technology advances, hydraulic breaker bits continue to evolve — offering greater strength, precision, and energy efficiency. With companies like Guangzhou Huilian Machine leading in innovation and quality, the future of hydraulic tool engineering looks stronger than ever.

External Link:

Learn more about hydraulic systems and maintenance at Construction Equipment Guide.

About

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

Getting started is easy

Contact with our experts to find the best excavator parts solutions for your needs. Discover how Huilian can enhance your equipment's performance and efficiency.

Get in touch

© 2025 HUILIAN MACHINE. All rights reserved