What are common failures of Excavator Breaker Parts in 2026?

- Understanding Excavator Breaker Parts: Common Issues and Procurement Strategies

- 1. What Are the Common Failures of Excavator Breaker Parts in 2026?

- 2. How Do I Choose the Right Excavator Breaker Parts?

- 3. What Are the Cost Implications of Excavator Breaker Parts?

- 4. How Do I Maintain Excavator Breaker Parts Effectively?

- 5. Where Can I Source Reliable Excavator Breaker Parts?

- 6. How Do I Ensure the Quality of Excavator Breaker Parts?

- 7. What Are the Benefits of Partnering with Huilian Machine?

Understanding Excavator Breaker Parts: Common Issues and Procurement Strategies

Excavator breakers are essential attachments for demolition and heavy-duty excavation tasks. In 2026, industry professionals face several challenges related to these components. Below are key considerations to ensure optimal performance and longevity of your equipment.

1. What Are the Common Failures of Excavator Breaker Parts in 2026?

Excavator breaker parts may experience various issues, including:

Hydraulic System Failures: Contaminated fluid, leaks, or pump malfunctions can lead to reduced efficiency. Regular maintenance and timely replacement of seals and filters are crucial.

Undercarriage Wear: Continuous operation in abrasive conditions can cause track and roller degradation. Implementing daily inspections and proper track tensioning can mitigate this.

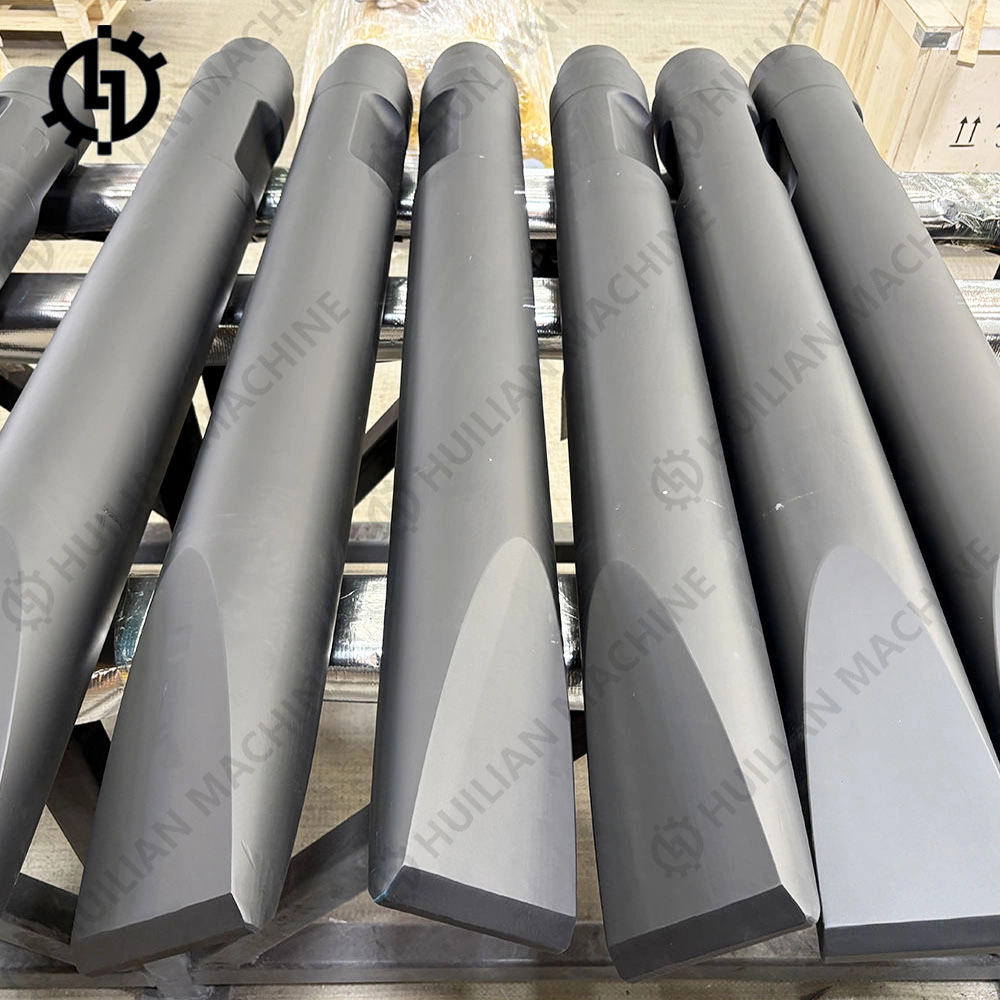

Attachment Failures: Worn-out breaker components, such as chisels and diaphragms, can hinder performance. Monitoring for signs like vibrations or hydraulic noise and replacing parts promptly is recommended.

2. How Do I Choose the Right Excavator Breaker Parts?

Selecting appropriate breaker parts involves:

Compatibility: Ensure parts match your excavator model and the specific tasks at hand.

Quality Assurance: Opt for parts from reputable manufacturers that provide quality control documentation.

Aftermarket vs. OEM: Evaluate the benefits of original equipment manufacturer (OEM) parts versus high-quality aftermarket options, considering factors like cost, availability, and performance. ((https://www.huilianmachine.com/top-wholesale-atlas-copco-breaker-parts.html?utm_source=openai))

3. What Are the Cost Implications of Excavator Breaker Parts?

Costs can vary based on:

Brand and Quality: OEM parts may be more expensive but offer guaranteed compatibility and durability.

Maintenance Practices: Regular upkeep can extend part life, reducing the frequency of replacements.

Supplier Relationships: Establishing connections with trusted suppliers can lead to better pricing and availability. ((https://www.huilianmachine.com/article/komatsu-hydraulic-breakers-parts-cost-top-buyer-insights.html?utm_source=openai))

4. How Do I Maintain Excavator Breaker Parts Effectively?

Effective maintenance includes:

Regular Inspections: Check for signs of wear, leaks, or damage.

Timely Replacements: Replace worn components like seals, diaphragms, and chisels to prevent further damage.

Proper Lubrication: Ensure moving parts are adequately lubricated to reduce friction and wear.

5. Where Can I Source Reliable Excavator Breaker Parts?

Consider sourcing from:

Authorized Dealers: For OEM parts, ensuring authenticity and warranty coverage.

Reputable Aftermarket Suppliers: Companies like Huilian Machine offer a range of high-quality aftermarket parts compatible with various excavator models. ((https://www.huilianmachine.com/top-10-excavator-hydraulic-breaker-manufacturers-brands-huilian-2.html?utm_source=openai))

6. How Do I Ensure the Quality of Excavator Breaker Parts?

To verify quality:

Request Documentation: Obtain quality control certificates and performance data from suppliers.

Conduct Sample Testing: Before bulk purchases, test parts to confirm they meet your standards.

Seek Third-Party Inspections: Engage independent inspectors to assess part quality and compliance. ((https://www.huilianmachine.com/top-wholesale-atlas-copco-breaker-parts.html?utm_source=openai))

7. What Are the Benefits of Partnering with Huilian Machine?

Huilian Machine offers:

Wide Compatibility: Parts and breakers for most leading international brands.

International Recognition: Exported to over 90 countries and regions, acclaimed for quality and diversity.

Technical Expertise: Experienced design, R&D, QC, and sales support teams.

OEM & Custom Solutions: Tailored technical solutions for specific machinery needs.

After-sales Service: Responsive support and global distributor partnership opportunities. ((https://www.huilianmachine.com/top-10-excavator-hydraulic-breaker-manufacturers-brands-huilian-2.html?utm_source=openai))

By addressing these considerations, industry professionals can enhance the performance and longevity of their excavator breakers, ensuring efficient and cost-effective operations.

Note: The information provided is based on industry best practices and may vary depending on specific equipment and operational conditions.

Data Sources:

About

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

Getting started is easy

Contact with our experts to find the best excavator parts solutions for your needs. Discover how Huilian can enhance your equipment's performance and efficiency.

Get in touch

© 2025 HUILIAN MACHINE. All rights reserved