What is a hydraulic breaker on an excavator | Huilian Guide

- What is a Hydraulic Breaker on an Excavator?

- Understanding Hydraulic Breakers

- Main Components of a Hydraulic Breaker

- Compatibility and Sizing

- Advantages and Considerations

- When to Use a Hydraulic Breaker

- Selecting the Right Breaker

- Industry Trends

- For optimal performance and durability, choose high-quality hydraulic breakers from trusted brands and maintain rigorous upkeep routines.

- Sources:

- Looking for more guidance on selecting or maintaining hydraulic breakers for your operations? Contact Huilian’s industry experts for tailored advice.

What is a Hydraulic Breaker on an Excavator?

This guide answers what is a hydraulic breaker on an excavator—clarifying its function, key parts, and use cases. Understand performance, maintenance, and selection for optimal results. Professional users need to know how hydraulic breakers drive efficiency and long-term savings in tough demolition and quarry applications.

Understanding Hydraulic Breakers

- Definition:

- A hydraulic breaker (also known as a rock breaker or hydraulic hammer) is an attachment for excavators.

- It uses hydraulic pressure to power a piston, delivering a strong impact force to break hard materials.

- Primary Uses:

- Demolition of concrete, rocks, and structures

- Breaking up asphalt, pavements, and roads

- Trenching and mining operations

- Secondary breaking in quarry sites

- Key Benefits:

- Increases excavator versatility

- Reduces manual labor and time

- Ensures precision, control, and operator safety

Main Components of a Hydraulic Breaker

- Hydraulic Cylinder:

- Converts hydraulic energy from the excavator to mechanical movement in the breaker.

- Piston:

- The moving part that delivers impact blows to the tool (chisel or blunt).

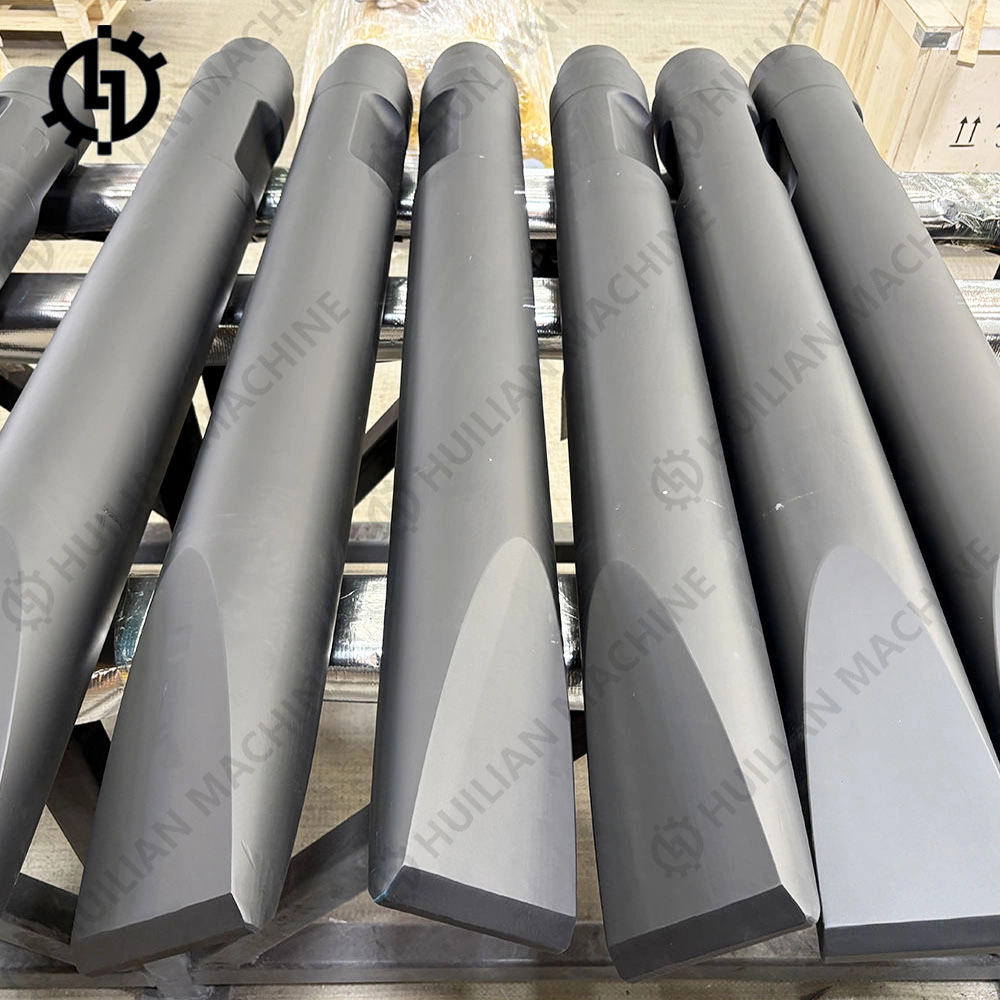

- Tool/Chisel:

- The direct contact point against the material, available in different shapes for varied applications.

- Mounting Bracket:

- Connects the breaker securely to the excavator arm.

- Accumulator:

- Stores pressurized hydraulic fluid, reducing vibration and improving efficiency.

Compatibility and Sizing

- Excavator Match:

- Always choose a breaker size compatible with the excavator’s operating weight and hydraulic output.

- Manufacturers like Komatsu, CAT, and Volvo provide compatibility charts (source: (https://www.cat.com/en_US/products/new/attachments/breakers.html)).

- Application Needs:

- Heavier breakers for primary demolition; lighter models for trenching and roadwork tasks.

Advantages and Considerations

- Operational Efficiency:

- Power output and blow frequency directly affect productivity.

- Modern breakers feature energy recovery systems for higher efficiency (source: (https://www.epiroc.com/en-us/products/attachments/hydraulic-breakers)).

- Maintenance Needs:

- Regular inspections for wear, leakage, and tool condition ensure long service life.

- Use manufacturer-recommended hydraulic oil and spare parts to prevent downtime.

- Site Safety:

- Proper attachment and use minimize risk of injury or machine damage.

- Operators should be trained on best practices and safety standards (refer to (https://www.osha.gov/)).

When to Use a Hydraulic Breaker

- Best For:

- Projects demanding high breaking force in confined or tough environments

- Removing reinforced concrete slabs or foundations

- Quarrying oversized rocks or boulders

Selecting the Right Breaker

- Key Factors:

- Material hardness and thickness

- Frequency of use

- Excavator hydraulic flow rates

- Availability of spare parts and aftersales support

Industry Trends

- Recent Developments:

- Increased focus on noise reduction and vibration control

- Adoption of smart monitoring systems for maintenance alerts (source: (https://www.constructionequipmentguide.com/)).

For optimal performance and durability, choose high-quality hydraulic breakers from trusted brands and maintain rigorous upkeep routines.

Sources:

- (https://www.cat.com/en_US/products/new/attachments/breakers.html)

- (https://www.epiroc.com/en-us/products/attachments/hydraulic-breakers)

- (https://www.osha.gov/)

Looking for more guidance on selecting or maintaining hydraulic breakers for your operations? Contact Huilian’s industry experts for tailored advice.

About

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

Getting started is easy

Contact with our experts to find the best excavator parts solutions for your needs. Discover how Huilian can enhance your equipment's performance and efficiency.

Get in touch

© 2025 HUILIAN MACHINE. All rights reserved