What is the efficiency of a hydraulic hammer? | Huilian Guide

What is the Efficiency of a Hydraulic Hammer?

In the excavator part industry, understanding the efficiency of a hydraulic hammer is essential for maximizing productivity, reducing costs, and prolonging equipment lifespan. This article explains what hydraulic hammer efficiency means, how it is measured, key variables that influence it, and industry benchmarks—providing actionable insights for excavator professionals.

What is Hydraulic Hammer Efficiency?

- Definition:

Hydraulic hammer efficiency refers to the ratio of useful breaking energy delivered to the workpiece versus the hydraulic input energy consumed from the excavator.

- Typical Range:

Modern hydraulic hammers generally operate with an efficiency of 60-85% (Source: Caterpillar, Komatsu technical brochures).

- Measurement Units:

Expressed as a percentage, or in terms of energy-per-blow (joules or ft-lb per cycle).

Factors Influencing Hydraulic Hammer Efficiency

- Hydraulic System Quality:

Properly maintained, high-quality systems reduce energy losses due to heat, friction, and hydraulic fluid flow inefficiencies.

- Pressure and Flow Settings:

Optimal pressure and flow rate align the hammer’s operating parameters with the specific excavator model, improving energy transfer efficiency.

- Hammer-Excavator Compatibility:

Matching hammer size and power requirements with the carrier excavator ensures peak efficiency.

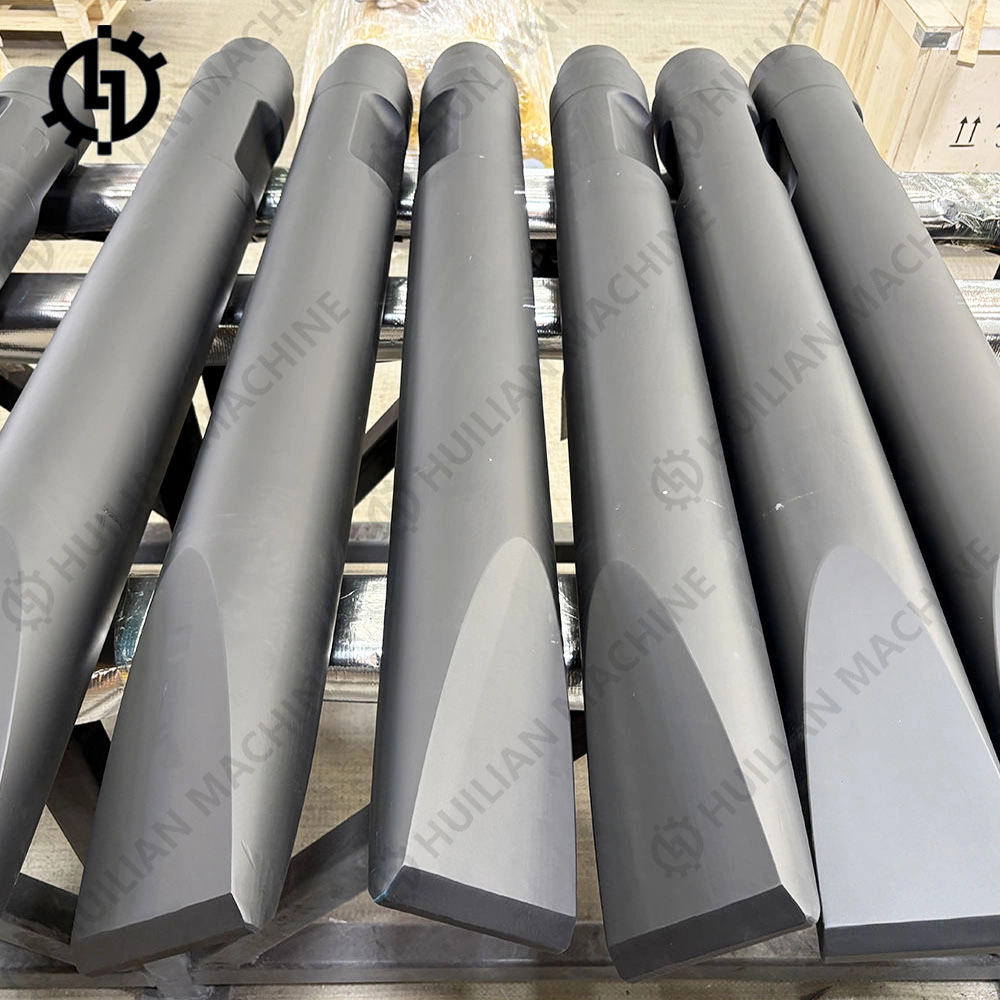

- Tool Condition:

Worn-out chisels, moils, or blunt tools absorb more energy, reducing effective impact and lowering efficiency.

- Operator Technique:

Skilled operation, such as maintaining correct alignment and avoiding blank firing, sustains higher efficiency.

- Ambient Temperature:

Extremely high or low temperatures can impact hydraulic fluid viscosity and system performance.

- Regular Maintenance:

Scheduled maintenance according to OEM recommendations helps preserve energy conversion rates.

How to Maximize Hydraulic Hammer Efficiency

- Routine Inspection:

- Regularly check hoses and connections for leaks.

- Replace worn seals and parts to prevent internal leakage.

- Proper Lubrication:

- Use manufacturer-recommended lubricants.

- Lubricate bushings and tool points frequently for smooth operation.

- Match Hammer to Application:

- Use the right size and type of hammer for the material and job scope.

- Monitor Hydraulic Fluid:

- Change hydraulic fluid at OEM intervals.

- Check for contamination that could cause efficiency loss.

- Train Operators:

- Invest in operator training for better control and reduced misuse.

Industry Benchmarks and Data

- Standard Efficiency Ratio:

- According to (https://www.komatsu.com/parts/hydraulic-excavator/) and (https://www.cat.com/en_US/products/new/attachments/hammers.html), hammers peak at 80-85% efficiency under ideal conditions.

- Impact Energy/BPM (Blows Per Minute):

- Modern models deliver energy per blow of 350–8000 joules (258–5900 ft-lb), with efficiency maximized at manufacturer-set hydraulic parameters.

Key Takeaways

- Regular maintenance, proper tool selection, and skilled operation raise hydraulic hammer efficiency.

- Professional excavator part managers should monitor system parameters for cost-effective, sustainable operation.

- Consult with trusted suppliers like Huilian for OEM-compatible parts and technical support.

For more guidance on excavator part efficiency and expert-approved components, contact the Huilian team.

About

What is your shipping and delivery time?

We offer fast and reliable global shipping. Delivery times vary depending on location and order size, but we strive to process and ship orders as quickly as possible.

Do you offer OEM and aftermarket parts?

Yes, we manufacture high-quality OEM parts and supply aftermarket parts from top brands such as NOK, Parker, SKF, and Hallite to ensure optimal performance.

Are your parts compatible with all excavator brands?

Yes, our parts are designed to be compatible with major brands like Komatsu, Caterpillar, Hitachi, Hyundai, Doosan, JCB, Kobelco, Sany, and many more.

What types of excavator parts do you offer?

We provide a wide range of high-quality excavator parts, including hydraulic breakers, chisels, seal kits, diaphragms, pistons, wear bushes, retainer bars, through bolts, side bolts, valves, and liners.

How can I ensure I’m selecting the right part for my equipment?

Our expert team can assist you in finding the right part based on your machine model, specifications, and requirements. Contact us for personalized support.

Getting started is easy

Contact with our experts to find the best excavator parts solutions for your needs. Discover how Huilian can enhance your equipment's performance and efficiency.

Get in touch

© 2025 HUILIAN MACHINE. All rights reserved